Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

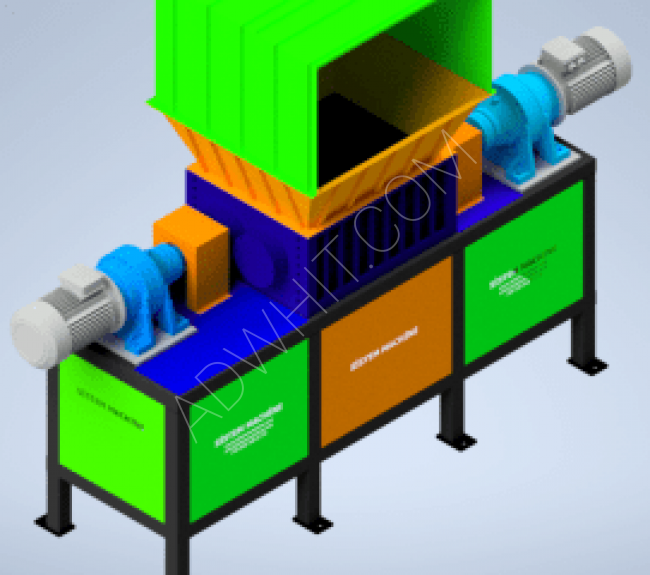

Plastic granules production line

Parts included in the integrated line:

- Spiral conveyor belt.

– Forced feeding system.

– Extruder for cutting using air.

– Cooling tank.

– Vibrator with air cooling.

- Air blower.

– Collection tank.

– Control panel: Standard electrical distribution with an independent main control panel.

Technical specifications of PVC granules plant production line

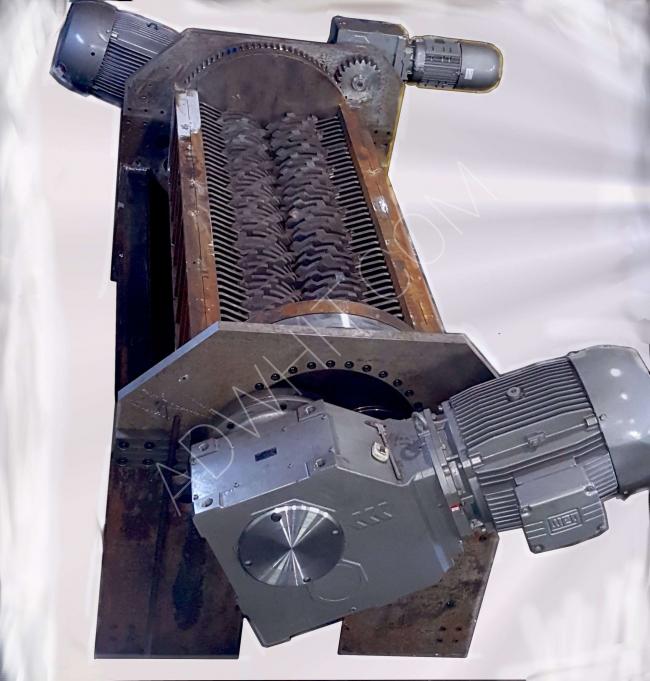

– The engine is directly connected to the gearbox, allowing power to be transmitted directly to the snail.

– The machine is equipped with a water cooling system, which increases the stability of the production process.

This system ensures that materials are continuously fed to the snail, which increases production capacity and product quality.

– Extruder power: 150 kW, with inverter.

Forced feeding system capacity: 5 kilowatts, with inverter.

– Helix: diameter 150 mm, length to diameter ratio 28:1, made of SACM1, treated with nitrating, honing and polishing, hardness after heating 63 – 65

– Heater capacity: 62 kW

– Air blower for transporting granules: capacity 625 kW.

– Vibrating unit capacity: 75 kilowatts.

- Production capacity reaches

Contact Al-Farouk Company now and learn all the details about the plastic granules production line