Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

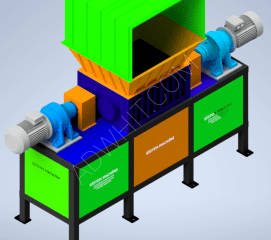

DUAL ROTOR SHREDDER

Double rotor shredder

The plastic machine allows chocks, big bags, FILM (Nylon), car tires, ropes and similar materials to be broken into pieces easily. In addition, by using the double rotor shredder before the Crushing Machine, both the capacity is increased and the blade life of the Crushing Machine is extended. These machines have two types of rotor drive types, driven by a reducer motor or a hydraulic system reducer type, depending on the situation. Depending on customer requests and demands. According to the double rotor shredder, blade and rotor dimensions and dimensions, the engine power varies accordingly. It has a PLC controlled electrical panel. Externally mounted roller bearings are cleaned of dust. They have bearings that can operate under heavy conditions. The machine has a large feeding chamber. The material to be shredded can be fed into the machine by conveyor and other Fork-lift equipment. The shredded product can be transported by screw, fan or conveyor. The materials crushed in the shredder machine are reduced to the desired size depending on the blade structure. In case of possible jamming, the rotor turns in the opposite direction and tries to eliminate the jamming. If the jam is not cleared, the machine will give an audible warning and stop automatically.

GENERAL FEATURES

- It has a PLC controlled electrical panel.

- Externally mounted bearing housings are kept dust-free. They have bearings that can operate under heavy conditions.

- The machine has a large feeding chamber.

- The material to be shredded can be fed into the machine by conveyor and other Fork-lift equipment.

- The shredded product can be transported by screw, fan or conveyor.

- The materials crushed in the shredder machine are reduced to the desired size depending on the blade structure.

- In case of possible jamming, the rotor turns in the opposite direction and tries to eliminate the jamming.

- If the jam is not cleared, the machine will give an audible warning and stop automatically.

- Thanks to the blade type and shredding chamber selected according to the characteristics of the material to be processed, it works with high efficiency on materials of different types and forms.

- It has low operating costs thanks to the blades made of special alloy steel material. The blade model and material are selected according to the type of material to be chopped.

Thanks to heavy-duty reducers and shock-absorbing wedges, the dynamic load occurring during shredding is prevented from damaging the machine. Thanks to inverter-controlled motors, energy efficiency is maximized. Thanks to PLC control, in case of possible material jamming or overloading, the rotors move in the opposite direction and automatically eliminate the jam.