Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

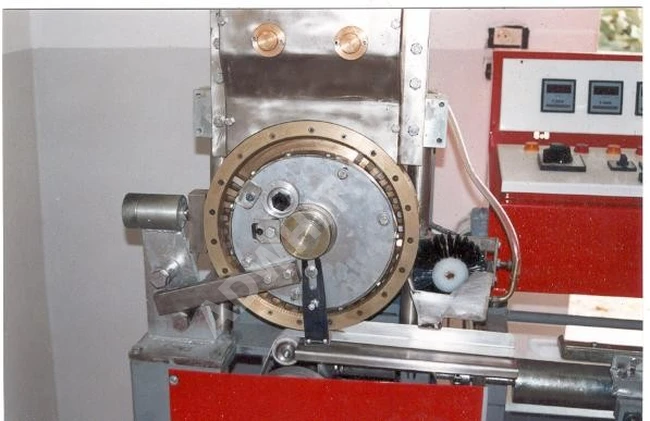

Turbo Marshmallow Mixer 500 liters/hour

Turbo mixer

*Our mixers are both manual and fully automatic machines.

After turning on the mixer, the only thing that needs to be done is to adjust the amount of production to be produced.

*In automatic mode, all the user has to do is enter the desired capacity and product density at the output on the touch screen.

* The intelligent control system calculates the pump speed and amount of air required, and takes the appropriate amount of air/dough mixture to the aeration head.

*Thanks to the system, the density of the blown product remains constant and homogeneity of the mixture is guaranteed.

* The rotor and pump are controlled by a speed controller in order to make precise settings for product density, structure and capacity.

*All settings are made via touch screen.

* Saves time because it is easy to clean.

*In order to maximize cooling or heating, both the rotor and stator of the mixer are designed and manufactured with water walls.

*At the mixer outlet it is used to reduce the product pressure and transfer the pneumatic dough to the next unit at the required pressure.

There is a counter pressure unit designed.

*Our mixers are produced in a standard way and can also be redesigned according to customers' special requests.

Can be configured.

*OMRON PLC panel and HMI panel are used.

*All body and its parts are made of 304 stainless steel.

* Production capacity 500 liters/hour. Productivity may vary according to type.