Property for Sale

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

US Dollar

43.1693

Euro

50.3978

Saudi Riyal

11.5244

Pound Sterling

58.1903

Kuwaiti Dinar

140.4663

United Arab Emirates Dirham

11.7583

Egyptian Pound

0.9161

Iraqi Dinar

0.0329

Bahraini Dinar

114.5044

Qatari Riyal

12.2490

Libyan Dinar

7.9417

Omani Rial

112.2739

Jordanian Dinar

59.2011

Algerian Dinar

0.3320

Moroccan Dirham

4.6834

Syrian Pound

0.3736

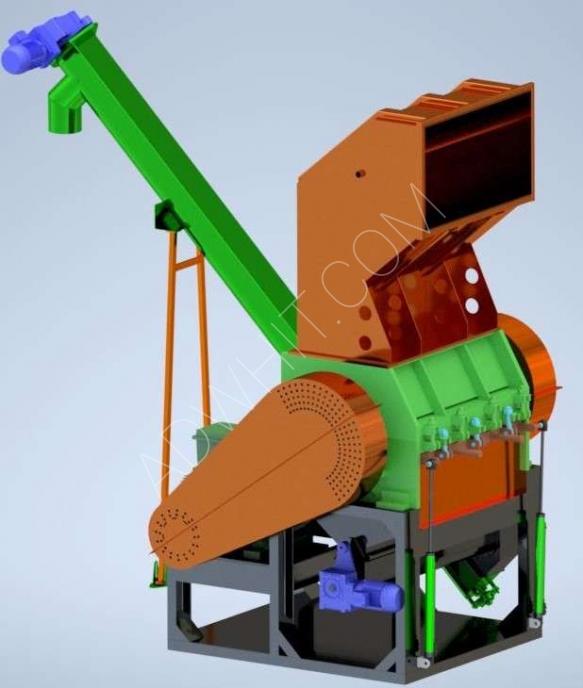

PLASTIC CRUSHING MACHINE

İstanbul / Başakşehir

Status

New

Advertiser

Manufacturer

Brand

SİSTEM MACHİNE

Details

Address

İstanbul / Başakşehir / İkitelli osb mah.

Offer number

00377424

Offer date

2024/03/07

Year

2024

Communication Languages

PLASTIC CRUSHING MACHINE

Plastic crushing machine is one of the important machines used especially in recycling. PLASTIC CRUSHING MACHINE The life of the machine is extended with its compact body design, special bearings and strong rotor design. In the Plastic Crushing Machine, the components are broken with a complete scissor movement between the rotating and fixed blades positioned at opposite angles to each other. In this way, equal sized crushed product is obtained. This method reduces excessive heat, dust and noise generation, which reduces the quality of the broken product, and also provides savings in energy consumption.

PLASTIC CRUSHING MACHINE General Features

- Plastic Crushing Machine manufacturing has a wide range, starting from 80 kg/hour to heavy duty crushers with a capacity of 2000 kg/hour and above.

- Plastic Crushing Machine is produced in 40-50-60-70-80-100-120-150-160 cm sizes.

- Starting from medium-sized Crushing Machines, blade replacement is also made easier thanks to the upper body that can be easily opened with the hydraulic power unit controlled via the Electric Panel.

- Heavy-duty bearings easily absorb vibrations and shocks caused by breaking. The fact that the bearing housings are separate from the crushing chamber allows the material to be washed by crushing with water.

- Depending on the characteristics of the material to be broken, Straight, Curved or V type Rotor designs with three or more rows are available.

- Thanks to the Rotors designed in size appropriate to the type of plastic crushing machine, great energy savings are achieved.

- The knives are produced from DIN 2379 (AISI D2) material, which has been increased to 58 HRC hardness by a thermal system and is precisely ground.

- The products coming out of the crushing machine are transferred by the crusher screw or fan system.

- It has an easily removable and attachable sieve system.

- The strong steel chassis, manufactured using the MIG Welding method, is mounted on vibration and shock absorbing feet.

- Every point of our machines can be easily accessed for maintenance and cleaning. It requires minimum maintenance during service.

- Safety Switches on the machine provide maximum occupational safety for the user during use and maintenance.

Similar offers

Plastic recycling line

0

TL

New

Manufacturer

Etimesgut, Ankara

2025/06/09

Plastic granules production line

0

TL

New

Manufacturer

Şehitkamil, Gaziantep

2024/05/15

Raw Material Mixer

34,092.24

TL

New

Manufacturer

Karatay, Konya

2024/04/16

Dishwasher and Washing Fragrance Capsule Production Machine

300,000

TL

New

Owner

Tuzla, İstanbul

2024/03/08

PLASTIC RECYCLING LINE

4,977.27

TL

New

Manufacturer

Başakşehir, İstanbul

2024/03/07

PET CRUSHING AND WASHING LINE

4,977.27

TL

New

Manufacturer

Başakşehir, İstanbul

2024/03/07