Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

Potato chip production line with a capacity of (50 - 2000) kg

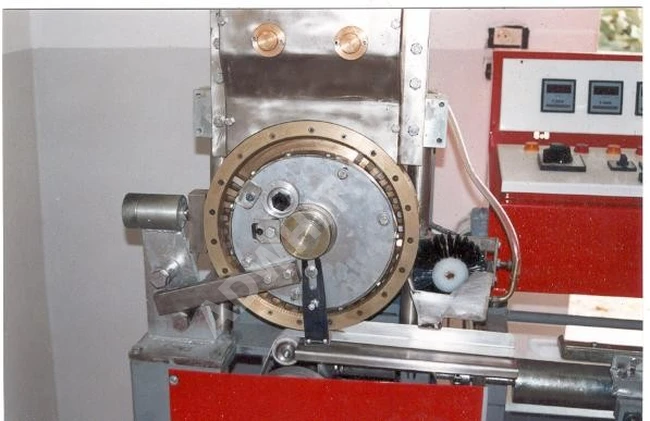

French fries production line is a good assistant for the production of French fries. It helps small and large potato chips processing plants to produce chips. The complete set of French fries production line consists of potato cleaning and peeling machine, potato cutting machine, blanching machine, drying machine, frying machine, de-oiling machine, seasoning machine, packaging machine and auxiliary equipment.

The capacity of the complete French fries production machine can reach 50kg/h~2t/h. Low one-time investment, low energy consumption, many functions, small size, high profit, convenient operation and maintenance, etc. have advantages.

Specifications:

1 Introduction to French Fries Production Line

2 Application of French Fries Production Line

3 French Fries Processing Steps

4 Small-scale Frozen French Fries Production Line

4.1 Small-scale Frozen French Fries Production Line Production Steps

4.2 Technical Parameters of 50kg/h Semi-Automatic French Fries Production Line

4.3 Advantages of Semi-Automatic French Fries Processing Line

5 Fully Automatic French Fries Processing Plant

5.1 Production Steps of Fully Automatic French Fries Production Line

5.2 Parameters of 300kg/h Large Automatic French Fries Processing Plant

6 Advantages of Automatic French Fries Production Line:

6.1 Automatic Frozen Chips Plant and Special Processing

Introduction to French Fries Production Line

There are semi-automatic and fully automatic production lines in French Fries production line. The semi-automatic small-scale French Fries production line is mainly composed of semi-automatic potato processing machines. It requires manual operation of the machine, and has low investment cost and less floor space. Its output ranges from 50kg/h to 500kg/h.