Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

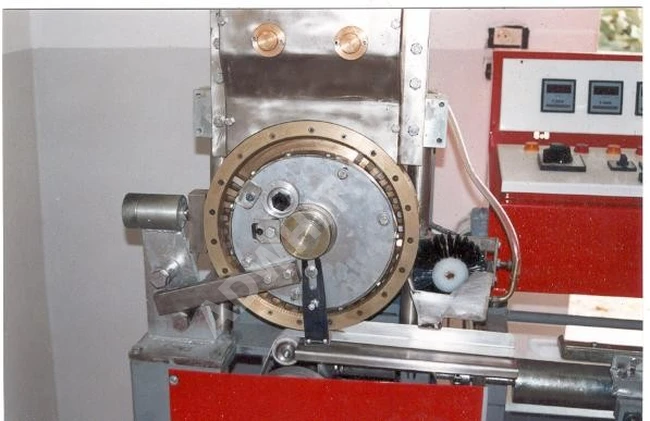

Pasteurizing eggs 1000 liters/hour

Egg pasteurizer with a capacity of 1000 liters/hour

Purpose and capacity: It is used for pasteurizing liquid egg products (egg white, egg yolk, whole egg). The pasteurization capacity is 1000 liters per hour.

Pasteurization process:

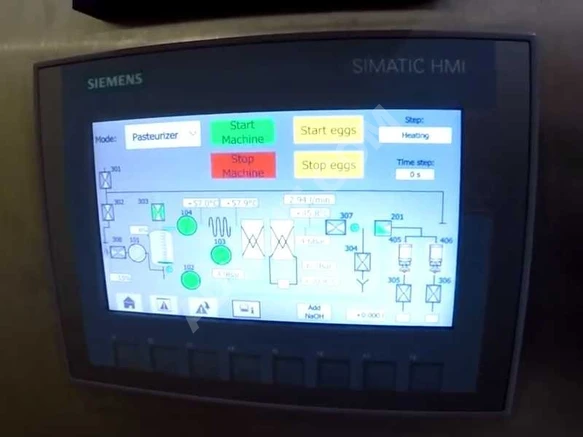

It is operated by the machine operator via the control panel.

Egg products are filled from the storage tanks to the balance tank of the pasteurization system using a transfer pump.

The pump is controlled by automatic level controls in the balance tank.

The product is sent to the regeneration section of the heat exchanger using a positive vacuum pump.

Here the temperature of the egg fluid is raised to approximately 50°C - 55°C.

After the regeneration section, the product is homogenized and reaches the rotary spinning heater, where its temperature rises to 67°C.

The product enters the holding tubes for 3 minutes and is then cooled.

In the refrigeration department, the product is cooled to 2-4°C and packed or sent to the warehouse.

Features:

Does not require a separate boiler for hot water.

There is no need to purchase a blender.

Provides precise temperature control.

It has minimal installation time.

Suitable for producing high quality egg products.

Filling can be done easily using the built-in filling unit.

Thanks to its compact design, it can fit into small spaces.

It can be pasteurized at high temperatures without the need for long-term cleaning.

Technical specifications of the PS 1000:

Electrical specifications of the machine: 15 kW

Capacity 1000 litres

Air pressure 6 bar - 30 Nm2/h

Inlet temperature 14°C

Pasteurization temperature 63-67°C

Outlet temperature 2-4°C

It takes 3 minutes