Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

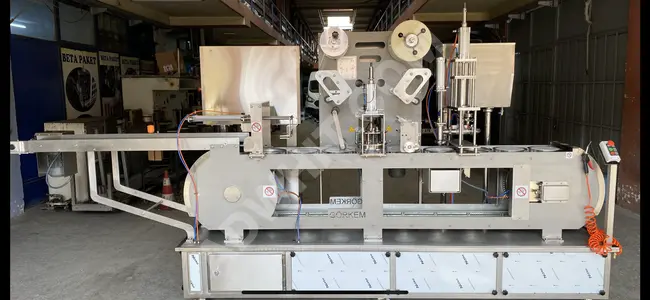

Paper and cardboard cup manufacturing machine

AL-DP100 Paper Cup Machine (3-9oz capacity)

Our prices do not include shipping, customs costs, and value added tax

Equipment selection price

Copper heater: 6,500 USD

Ultrasound package: USD 8,500

Ultrasound set + PLC + touch screen: USD 10,500

Ultrasound Plc Kit Touch Screen Aluminum Cover US $11,000

Features:

The working principle of our paper cup machine is that the main motor drives the whole machine, ensuring the perfect integration of gear and cam structures. The machine now uses a single aluminum plate instead of the previous three-plate machine; This greatly reduces the machine failure rate and reduces operator training time. This machine has 10 stations, 10 stations for grinding tools and 5 sets of stations for pre-heating. The working speed of the machine is increased to 90-120, and the 3-16oz single and double coated paper cups can be customized according to customer requirements. It is a fully automatic paper cup forming equipment using automatic multi-row paper feeding, paper reversing device (to ensure accurate positioning), copper strip or ultrasonic welding, automatic paper tube conveying, oil filling, bottom punching, bottom folding. Continuous processes such as preheating and winding can stably produce paper cups of different specifications. It is a paper cup equipment independently developed by our company, which has undergone comprehensive technical improvements to improve the stability of the whole machine.

The working principle of our paper cup machine is that the main motor drives the whole machine, achieving the perfect combination of gear structure and cam. The machine now uses a single aluminum disc instead of the previous three-disc machine. The machine failure rate is greatly reduced and operator training time is reduced. This machine has 10 stations, 10 stations grinding group, the flower is folded against preheating, and the working speed of 5 stations machine is increased to 90-120 boxes. Can be customized into single and double paper cups in 3-16oz size according to customer's request. It is a fully automatic paper cup forming equipment through multiple automatic paper, paper return device (ensure accurate positioning), ultrasonic welding or brazing, mechanical paper reel. The continuous process of conveying, oil injection, bottoming, folding, preheating, rolling, cupping and discharging can produce stable production of different specifications of paper cups, and after comprehensive technical improvement, our company's independent research and development can improve the stability of paper cup equipment.