Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

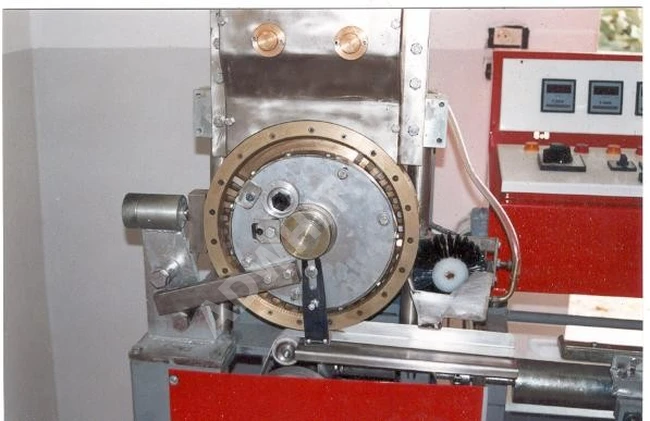

Waffle batter mixer 150-600 liters/hour

The wafer dough is mixed evenly and transferred to the oven with the help of dough pump through stainless steel tubes.

Automation includes dough mixer, dough transfer pump, dough storage tank, and stainless steel piping.

The ingredients in the dough recipe are placed in the mixer manually or automatically. The dough is mixed according to the specified process.

It is transferred to the storage tank with the help of pump. The dough is continuously fed to the wafer baking oven with the help of the pump.

The dough chamber of the wafer baking oven is controlled with the help of sensor and valve, and the excess dough is returned to the storage tank through stainless steel pipes.

The dough mixer takes water automatically and the values written on the control panel can be easily followed.

Types of machines:

Dough mixer 100 liters 400 liters/hour

Dough mixer 150 liters 600 liters/hour

Dough storage tank 200 liters 600 liters/hour

Dough automation power 6.5 kW

It is the facility needed to mix wafer dough homogeneously and automatically feed it to one or more wafer baking ovens.

The facility contains a dough mixer, dough feed pump, dough rest tank, and delivery piping.

The materials needed for the dough sample are placed in the mixer manually or automatically.

The raw materials are then mixed thoroughly and efficiently in a delicate process.

After that, the homogenized wafer dough is pumped to the break tank, and from there it is continuously fed to the automatic wafer baking oven with the help of another pump.

Payment method in Türkiye: 50% down payment and 50% after loading