Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

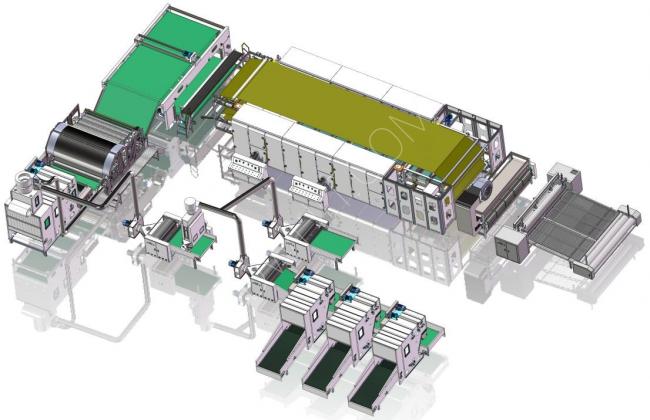

Ultrasonic upholstery machine for ultrasonic edge cutting and dimensioning

1. Integrated with ultrasonic quilting and ultrasonic edge welding

It's done together in an instant.

2. Latest structure design with gap adapters,

Smooth and wrinkle-free engraving.

3. The cylinder is equipped with an elevator for quick height adjustment

Set the roller to the horizontal level.

4. Different pattern designs can be made by simply changing them.

Pattern reel.

5. Configured with 2KW ultrasonic generators, powerful

Excellent welding effect.

6. The position of the edge cutter can be manually adjusted for different cutting operations.

Cutting requirements.

7. Max. Working speed: 9m/min. (regarding materials and resources)

thickness.)

8. Automatic scrap collecting device on both sides, convenient

Advanced treatment.

9. High production efficiency, 3-5 times output than sewing machine.

10. After quilting, it can be connected to the cutting machine.

The finished product or connected to the winding device

Fabric rolls.

11. Ultrasound generators are placed at the upper end of the quilting machine.

The device and share the same cabinet, which looks nice

And it saves space.

12. Equipped with advanced, high-performance SICK light curtain device

Accuracy and ensuring worker safety.