Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

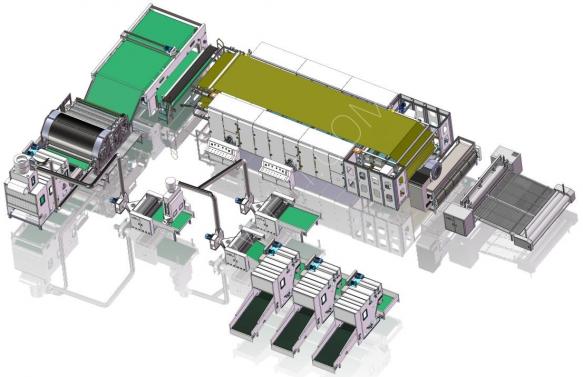

Fiber production line

Textile fiber bead machine for furniture and beds with a capacity of 300 kg / h

Thermal fiber production line

⦁ Raw materials: PET fibers with measurements 3-15D * 38-65mm and fibers with a low melting point

⦁ Product and application: thermal filler for insulation, home textiles, beds, furniture, etc.

⦁ Product Characteristics: 60-500GSM

⦁ Capacity: according to the standard, the maximum is 300kg / H for products over 6D and 250gsm, the daily production capacity is 6 tons / 20 hours of production

⦁ Finished product width: max. 3000 mm.

⦁Package opener (Electric weighing machine is used to open the fibers in bales in advance by electronic weighing system and then transfer the fibers to the next working procedure according to a certain ratio.

⦁ Technical data: working width: 1100 mm

Production capacity: 200kg / H (first class polyester 6D) weighing system: electronic control method: photoelectric

⦁ Structure

⦁ Q235-B steel sheet is laser cut and bent in a CNC machine, installed in the machine frame and assembled into modules.

⦁ The screw Cage is made of high-quality wood with a fabric lining and is surrounded by angular steel for support.

⦁ The transport cage is made of a wooden cage divided into two parts in the order of high and low sliding.

⦁ The diameters of the fiber centering roller and the scratching roller including the heights of the sharp points are 480mm and there are a total of 3 rows.

⦁ The feeding is automatically controlled by photoelectric and the spike cage, which controls the feeding amount, is controlled by a separate frequency converter.

⦁ The tanks are made of aluminum alloy and are controlled by pneumatic cylinders. Tanks are driven by automatic exhaust. Fiber shedding is not affected by air current. This makes the weight accurate

Front opener with lubricating device

⦁ The machine is used for pre-opening and mixing one or more types of fibers, which will be sent to the funnel of the large-chamber Mixer through the fiber conveying fan.

⦁ Technical data: working width: 1000mm opening method: pin plate for opening

Roller diameter: 450mm (including PIN plate height) roller opening speed: 1000rpm

Production capacity: 500kg / H (6D first grade polyester)

⦁ Structure

⦁ The frame is made of Q235-B steel plate with a thickness of 10 mm through qualitative processing and welding.

⦁ The feeding Cage is a leather cage matched with 3 sets of package openers to provide fiber.

⦁ The feeding cylinder is a φ120mm steel corrugated cylinder with an up and down counter pressure structure.

⦁ The opening roller is a φ450mm seamless steel pipe that is dynamically calibrated and balanced and compatible with fixed plates.

⦁ The conveying fan moves separately in line with the conveying air hose φ300mm and there is a strong magnet on the conveying piece.

⦁ The feeding is controlled by the photoelectric power of the large funnel mixing machine with a reverse switch.

Fiber assembly cabinet and Main opener

⦁ The machine is suitable for opening more materials coming from the large bowl mixer and will transfer the fibers to the storage room of the mixing machine through the fiber conveying fan.

⦁ Technical data: working width: 1000mm opening method: pin plate

Drum diameter: 450mm (including the height of the card PINs) drum opening speed: 1000rpm

Production capacity: 500kg / H (first grade 6D polyester)

⦁ Structure

⦁ The frame is welded with Q235 - B steel plate by qualitative processing

⦁ The feeding Cage is a leather cage compatible with the dust collection compartment.

⦁ The feeding cylinder is a φ120mm steel corrugated cylinder with an up and down counter pressure structure.

⦁ The opening roller is a φ450mm seamless steel pipe that is dynamically calibrated and balanced and compatible with fixed plates.

⦁ The transmission fan moves separately according to the transmission air hose φ300mm and there is a strong magnet in the transition part.

⦁ The feeding is controlled by the photoelectricity of the vibrating feeder.

Reverse gear switch.

Vibrator feeder

الفني technical date: working width: 1750 mm

Production capacity: 300kg / H (first class 6D polyester) control method: photoelectric

⦁ Structure

⦁ The machine casing is made of Q235-B steel sheet and has a modular assembly.

⦁ The toothed Cage is a high-quality wooden cage with a thick fabric support and a steel corner support.

⦁ The horizontal feeding Cage is high-quality, non-slip leather cages, one in front of the serrated cage and the other behind the serrated cage.

⦁ The diameter of the central pin and stripping rollers: Φ410mm, with three rows of pins on it, while the ends of the roller prevent fiber entanglement.

⦁ The vibration plate is made of stainless steel plate, polished and has no fiber sagging.

⦁ Two photoelectric are positioned relative to the collecting funnel and the feeding funnel, and the distance can be adjusted.

⦁ The worm wheel adjusts the width of the vibrating Hopper manually.

⦁ A high-level fiber storage funnel is added to the fiber feed Inlet and the fiber is connected by roller clamping.

Single cylinder Dover sieving machine

⦁ It is used to transform the resulting fibers into stable fiber layers by opening and combing them.

Single cylinder Dover sieving machine

⦁ It is used to open and comb the resulting fibers into fixed fiber layers consisting of single fibers and send them to the next process.

⦁ Technical standards:

⦁ Working width: 2000mm

⦁ Capacity: 300kg / H (based on 6D premium fiber) suitable fiber: 3-15D×38-65mm PET

⦁ Output speed: ≥45 m / min 3) structure features:

⦁ The machine body is made of high-quality steel, coiled, high-quality

Thermal stress is relieved and manufactured with high precision, as well as support.

⦁ The horizontal feeding Cage is a PVC cage equipped with a pressure roller for even feeding.

Nutrition

⦁ Four feeding rollers with a diameter of φ65 mm, an anti-metal protection device is used at the material inlet of the machine, which can test the metal and has an automatic stop warning.

⦁ Diameter of the main cylinder: 1230 mm

⦁ There are 5 pairs of working rollers and stripping rollers for the master roller. Five combing sections in total to comb the entire fiber and form the mesh evenly.

⦁ The edge suction system is equipped with 6 places and the dust particles should be transferred to the special dust cage.

⦁ Walking platforms are placed on both sides of the machine for maintenance.

Fiber boot 220*380

⦁ The machine is used to evenly fold the fiber webs and overlap them with a certain width and thickness to perform the following work.

⦁ Technical data: Inlet width: 2200mm

Output width: ≥3800mm winding speed ≥45m / min output speed: 1 ~ 10m / min

Feeding quantity: 60-500 g/m2

⦁ Structure

⦁ The machine body is made of Q235-Barmor plate with a thickness of 8 mm and connected by Iron corners.

⦁ Anti-static PU cages are intended for transportation, interference and balancing. The lower Cage has PVC slats.

⦁ Each cage drive cylinder, except for the winding cylinder, is made of seamless steel with a diameter of φ108 mm and reinforced in metal tip axles.

⦁ Cross interference and mutual movement is the subsection that is strictly controlled by PLC.

⦁ Reciprocating and cross-winding adopt synchronous driving belt.

⦁ The height of the lower Cage is electrically controlled by the motor.

⦁ There is a platform on both sides.

Connected convection furnace

⦁ Suitable for: heating fiber mesh and thermally bonding low melting point fibers to the filling with certain strength and certain properties.

⦁ Technical dimension: Working width: 3800 mm

Heating chamber length: 6000mm internal temperature: ≥ 220 degrees Celsius

Mechanical ascent speed: max 12 m / min

⦁ Structure and properties:

⦁ Single-layer drying area with upper blowing and lower suction method, hot air penetration and convection with high thermal efficiency. The tray-like air duct can be easily cleaned.

⦁ The main structure of the machine is welded from grooved steel and angle steel.

⦁ The transfer Cage is a single-layer Teflon mesh, which can withstand high temperatures and prevent the mesh from sticking to the cage with automatic correction.

⦁ The heat preservation board is made of cold-rolled steel. The thickness of the heat preservation plate is 10 cm; the inner part is filled with thermally insulating asbestos material and sealed with nitrile silicone rubber, which has high temperature resistance.

⦁ Heating method: natural gas with flame (two sets of proportional burners for air distribution and energy saving)

⦁ The main motor of the dryer is controlled by a gear reducer.

⦁ It is equipped with a cooling fan and a cooling water cylinder (external channel and circulating cold water layer specified by the buyer) at the grid outlet of the furnace to cool the grid and form a soft filler product.

⦁ The exhaust duct is located above the furnace.

Air cooling machine

1) this machine is used to cool the grate of the furnace. 2) technical data:

2)Cooling method: upper air blowing and lower suction. Working width: 3600mm

3) structure and properties:

⦁ The main frame is made of profile steel.

⦁ Blow into the channel up and down and suction separately.

⦁ Teflon conveyor.

Envelope and cutter

⦁ Usage: cutting, packaging, measuring the finished product of soft thermal filler.

⦁ Technical parameters: roll diameter: ≥2000mm

⦁ The main structure and principle of action:

⦁ The main parts of the machine are made of Q235-B steel sheet and side Rod.

⦁ Coupled to five longitudinal cutters controlled by air cylinder.

⦁ Electric cross-cutter for automatic cross-cutting and alternating thermal wire cutting depending on the product.

⦁ The length of the coil is controlled by a pulse counter and displayed by a digital electrical device.

Filling recycling opener

⦁ The machine is suitable for opening and recycling edge caps for needle-punched filling, spray-bonded filling and heat-bonded soft filling.

⦁ Technical data: working width: 1000mm

Opening method: wooden pin boards

Opening roller diameter: 500mm (with pin) opening roller speed: 900rpm

Production capacity: 100kg / H

⦁ Technical standards:

⦁ The machine frame is a welded and qualitatively processed q235-A armored plate.

⦁ The feeding Cage is a PVC cage equipped with a star-shaped pressure roller.