Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

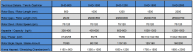

SINGLE ROTOR SHREDDER

Single Rotor Shredder

It is especially designed for breaking down factory waste and wedges. It is used to reduce the size of plastic wastes, such as cardboard, paper, textiles and chipboard. There are two types of rotor drives, driven by a reducer motor or a reducer type with a hydraulic system, depending on the situation.

Printing time, printing type and rotor speed are controlled by the PLC system and the correct parameters are loaded into the system by selecting the appropriate one from 3 different recipes according to the type of material being processed. Recipe parameters can be changed according to the different wastes processed.

Single rotor shredder machine, blade and rotor dimensions and dimensions vary according to customer requests and demands, and accordingly engine power varies.

In the single rotor shredder, the material to be shredded is pressed onto the rotor by the pressure unit driven by hydraulic power. In this way, the material to be shredded is pressed against the blades and high efficiency is obtained from the machine.

It has low operating costs thanks to its fixed and rotating blades, which are made of special alloy steel material and enable multiple use. By fixing the rotating blades on the rotor to the rotor with special connection cartridges, blade replacement is made easier and damage to the rotor is prevented. Different blade sizes and types are produced according to the type of material to be processed, and special alloy materials are used, taking into account the abrasive effects of the material.

Heavy-duty bearings are located in completely isolated bearings, thus preventing material transfer to the bearings and extending their service life. Thanks to heavy-duty reducers and shock-absorbing wedges, the dynamic load occurring during shredding is prevented from damaging the machine. Energy efficiency is maximized thanks to inverter-controlled motors