Property for Sale

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

US Dollar

34.5992

Euro

36.1823

Saudi Riyal

9.2165

Pound Sterling

43.6474

Kuwaiti Dinar

112.4034

United Arab Emirates Dirham

9.4175

Egyptian Pound

0.7008

Iraqi Dinar

0.0266

Bahraini Dinar

92.3384

Qatari Riyal

9.8732

Libyan Dinar

7.0868

Omani Rial

89.9031

Jordanian Dinar

48.7931

Algerian Dinar

0.2591

Moroccan Dirham

3.4402

Syrian Pound

0.0027

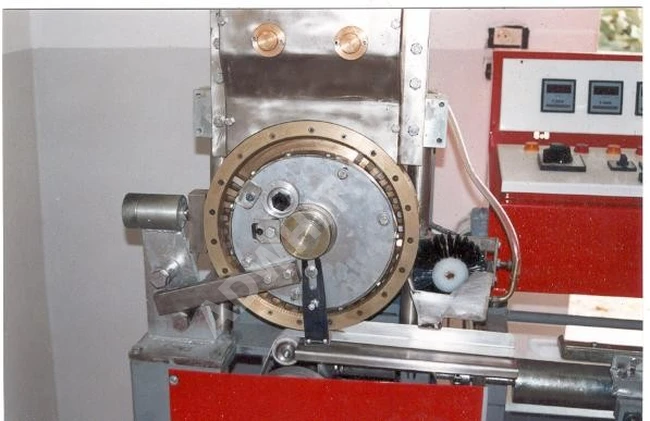

Samosa chips production line

1,312,493.40 TL

İstanbul / Esenyurt

Advertiser

Owner

Year

2023

Details

Address

İstanbul / Esenyurt / Orhan gazi mah.

Offer number

00353030

Offer date

2023/07/04

Communication Languages

Samosa chips production line

The line consists of 120 kg dough preparation tanks made of stainless steel. It mixes the materials and transports them through

A pump to the bread hoop made of iron that operates on gas and bakes the chips and then transfers them to the cooling belt

It is equipped with fans to cool the dough, and then the dough is transferred to the cutting and counting unit, where the chips are cut according to

.. 12-14- the required length and the required number - 10

The thickness of the dough produced is from 0.35 mm, with a production capacity of 60 to 80 kilos of dough per hour, and the electrical capacity

The line has a capacity of 9 kilowatts and it works on gas

Similar offers

Coffee grinder

44,300

TL

Used

Owner

Gaziosmanpaşa, İstanbul

2024/08/30

Coffee roasting machine

85,200

TL

Used

Owner

Gaziosmanpaşa, İstanbul

2024/08/30

Cream cheese chef (Stefan) Machine

0

TL

New

Manufacturer

Arifiye, Sakarya

2024/10/17

TYO – 40 CP Semi-Automatic Sugar Cube Machine

30,000

TL

New

Manufacturer

Yenimahalle, Ankara

2024/09/09

Pistachio and almond cutting machine into pine nut shape

4,000

TL

New

Manufacturer

Şehitkamil, Gaziantep

2024/09/30

Almond peeling tool (flasse)

3,500

TL

New

Manufacturer

Şehitkamil, Gaziantep

2024/09/28