عقارات للإيجار

سيارات للبيع

أثاث مستعمل

دراجات

آلات ومعدات

المهن والخدمات

فرص عمل

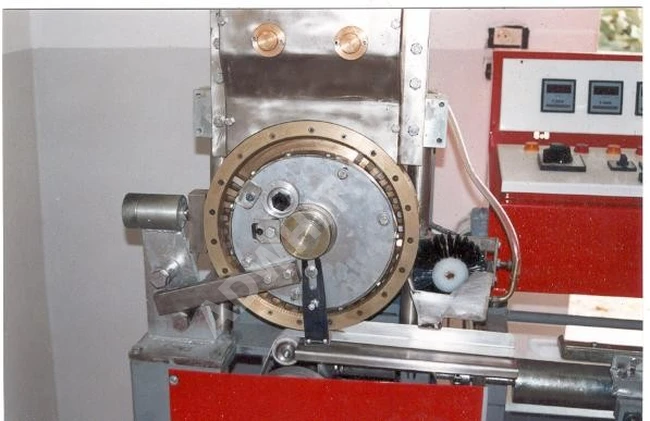

Automatic Round Can Seaming Machine

· The machine is made of stainless steel material for corrosion resistance wet or dry operations.

· Fully automatic filled can seaming machine is designed for seaming of round tin, aluminum or composite cans.

· During the seaming operation, the can is stationary and the seaming head is rotating aroud the can with four rollers.

· Stand alone machine with its own inlet and exit conveyor and a fully automatic can and lid feed.

· On the free stations, before the seaming operation, other modules such as filler, gassing or other customized special solutions can be implementable.

· The exit conveyor is ideal for product labeling by inkjet printer.

Functional Description:

ü The filled or empty can is fed to the machine by the conveyor.

ü A servo drive indexing star picks up the can and feeds it to various stations.

ü Simultaneously, a lid is taken from the magazine and positioned under the seaming station.

ü The can is lifted up, the lid is picked and both are pressed together against the seaming chuck and synchronous the seaming operation starts for airtight seam.

ü Then, system released and the indexing star passes the seamed can to the exit conveyor.

ü Quick and easy height, tool changing for different sizes.

ü Indexing star, lid feed, lifting table and seaming head drive by servo motor.

ü PLC controller with text display for settings and error messages.

ü CE-compliant in accordance with the design requirements of the machinery directive

ü Automation and servo motor Beckhoff-Germany, Pneumatic Festo-Germany, Bearing SKF-FAG or INA

ü Obtainable Production: up to 60 cans/minute

ü Can diameter range: 52 – 153 mm

ü Can height range: 50 – 220 mm

ü Motor Power: 2.2 kW