Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

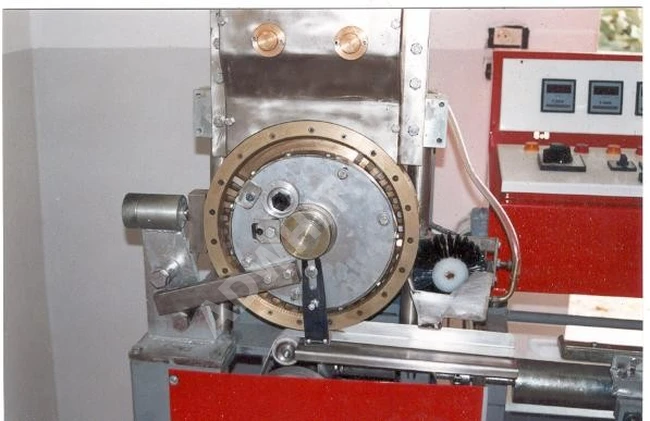

2.5 kW wafer cooling machine

Cooked wafer sheets are naturally cooled by placing them in cooling racks, which removes stress from the sheet.

In the input section, broken papers, half papers, papers that come in vertically, piled-up papers, and papers with broken corners are controlled by sensors to ensure that they are automatically removed from the system.

The number of conveyor plates ranges between 50 - 70 - 90 pieces, and they are made of stainless steel.

Power consumption 2.5 kW.

The template dimensions can be set to 290 x 470 – 350 x 470 – 350 x 500.

The wafer sheets are cooled after cooking. They are first cooled with air without using any additional cooling system.

Sheet coolers are designed with a spring-like shape to enable operators to move easily on the line. A monitoring device can be added at the entrance to this post-kiln controlled machine if necessary. For example, papers with broken corners can be guaranteed to be automatically removed from the system.

A special conveyor system separates the cooled wafer sheets and directs them to the creaming machine.

The number of effective conveyor plates is 40 or 90 pieces, and they are made of stainless steel.

Designed for dimensions 290x470 mm and 350x470 mm.

Payment method in Türkiye: 50% down payment and 50% after loading