Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

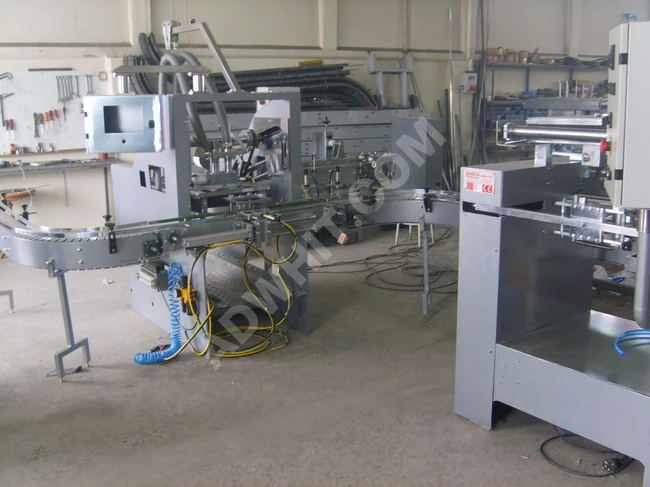

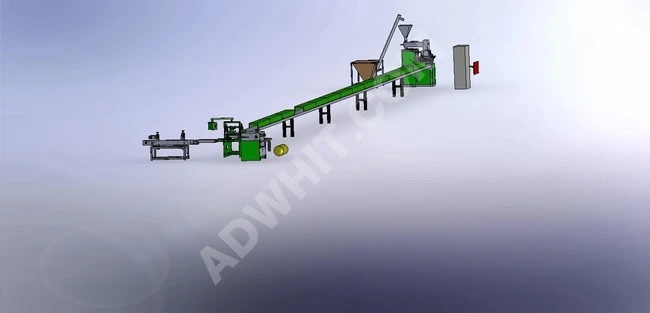

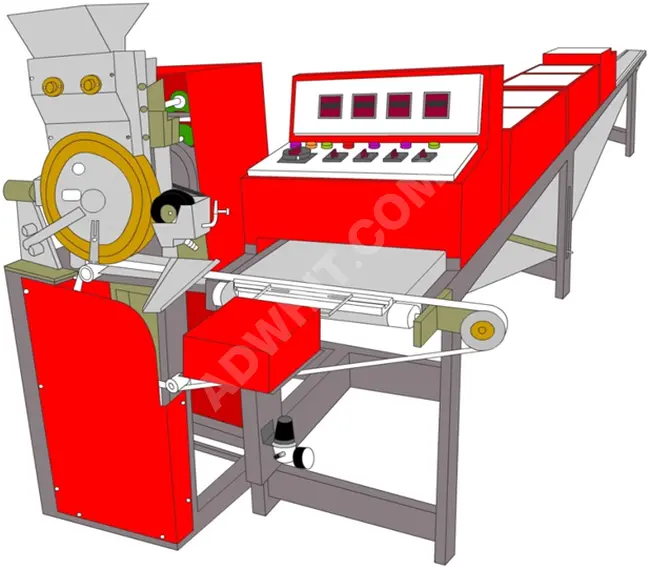

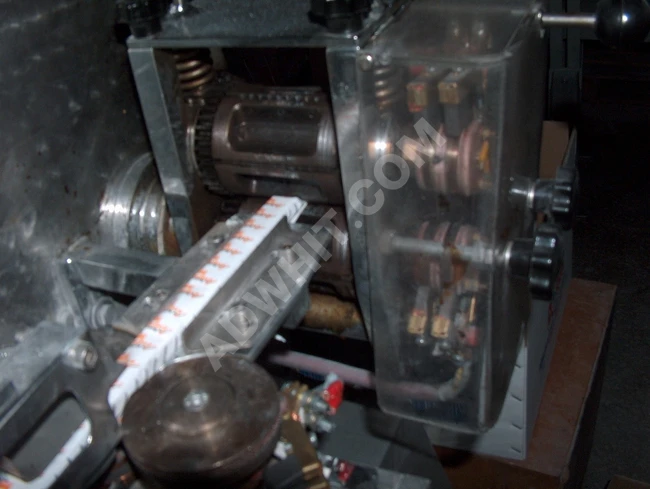

Automatic liquid filling machine with a capacity of 100-1000 cubic centimeters with servo support

Using the servo motor filling, capping and labeling machine, you can fill all liquid products in the food, chemical, pharmaceutical and cosmetic sectors, as well as cap and label the products...

Filling range 100cc-1000cc/1000cc-5000cc.

Number of filling nozzles: 4 – 6 – 8 pieces.

Conveyor length: 6 meters.

Electrical power: 3 kW.

Air consumption: 8 bar per 300 liters per minute

Working system: mechanical, electronic, electro-pneumatic.

Working air pressure: 6-8 bar.

The dosing tubes are made of high quality 304 stainless steel.

Bottle centering system.

Stainless link or plastic link conveyor upon request.

Servo motor filling and nozzles.

Bottom and top filling feature.

Weight adjustment through PLC control screen.

touch screen.

Filling speeds can be adjusted.

Optional full glass cabin.

The machine is installed on site by our assembly team, operational training is provided, and is delivered with instructions for use and maintenance.

The machines have a two-year warranty.