Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

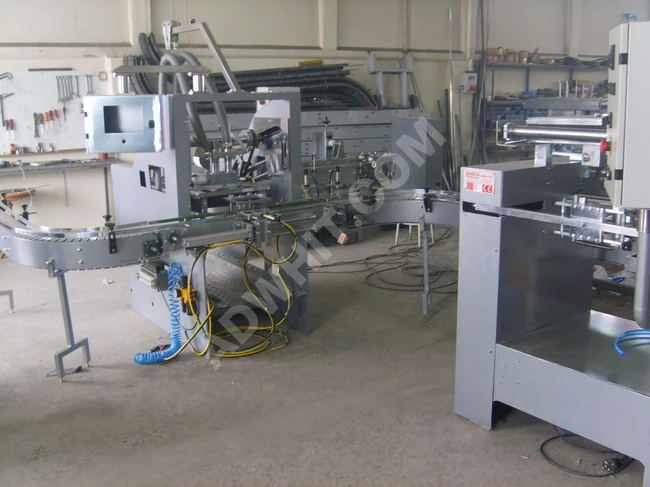

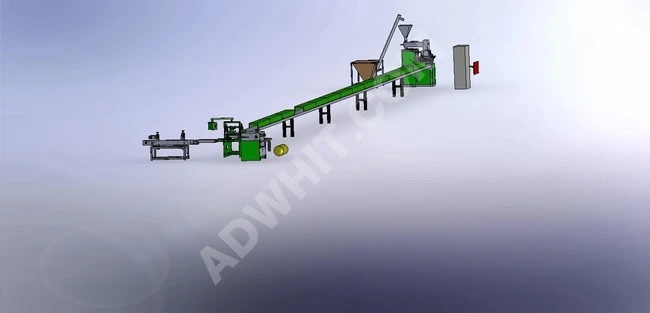

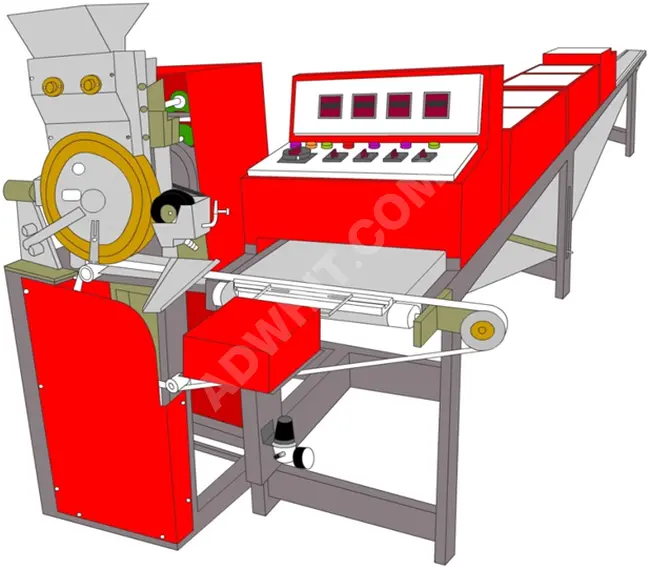

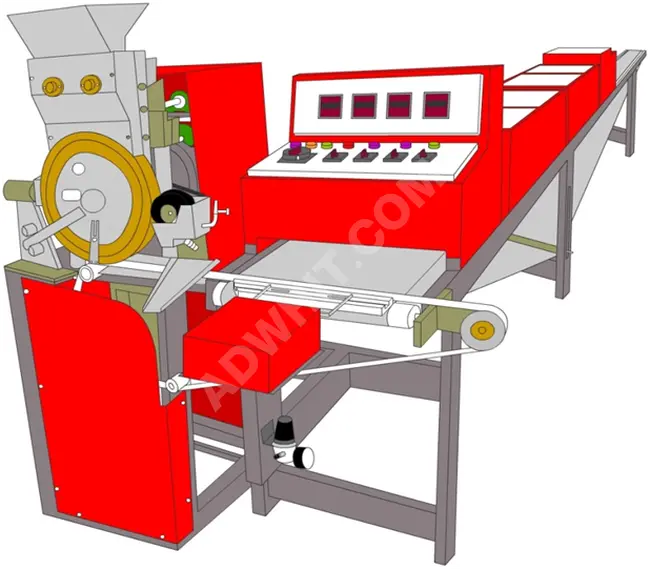

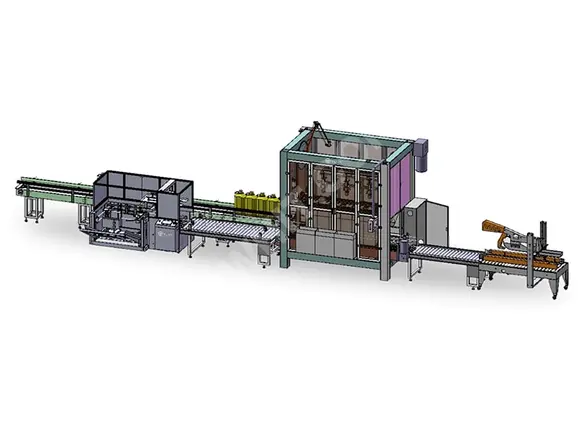

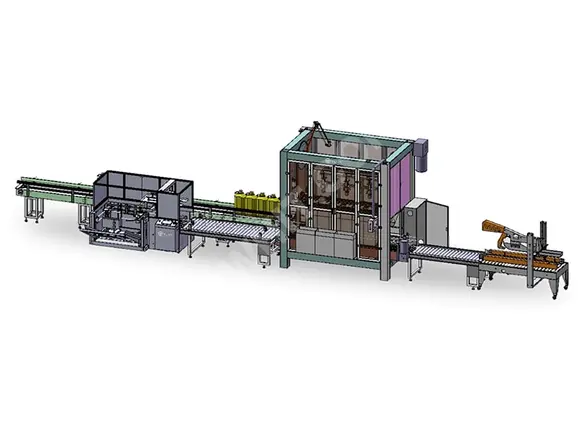

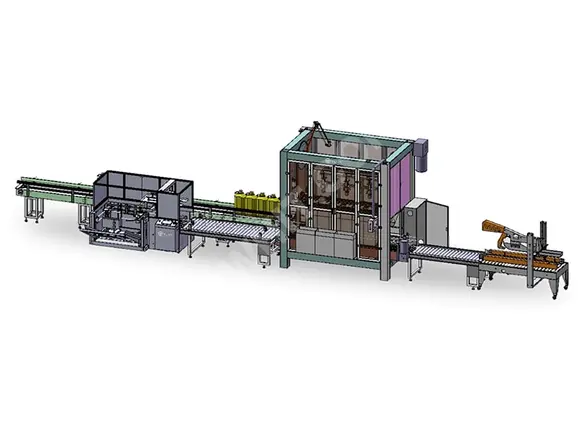

Three-head robot carton packing line 18-24 cartons per minute

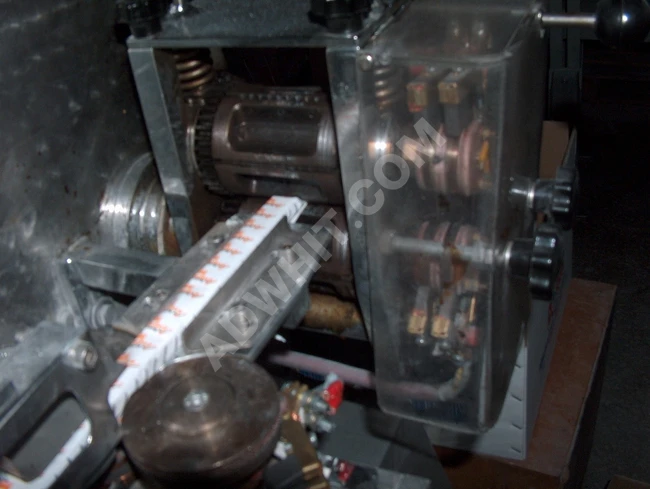

Three-head robot box packing line; Empty boxes are prepared automatically using a fully automatic box setting machine without manual intervention, and then transferred to a box packing robot. Products coming from the production line are automatically assembled into a suitable formation to be placed in boxes. The products are transferred to the cartridge robot, where they are held using suction systems, grips or magnetic grips specially designed for your products, and three boxes are packed at the same time. These operations are done without causing any harm to your products. As an additional option, two or more rows of products can be placed inside the box and a paper divider placed between them. After the products are packed into the boxes, the top covers are closed and secured with adhesive tape using a fully automatic box sealing and sealing machine, completing the production process. The main goal is to prepare your factory for the Industry 4.0 revolution, enabling low cost, low energy use, very high working speed, three times the efficiency and production of higher quality products. Your production planning ensures hygienic, clean production without manual intervention. We provide custom designs that perfectly match your production line and factory location.

Technical Specifications:

Operator control system: 10 inch PLC touch screen

Capacity: 18-24 boxes/min (for one layer)

Cartesian robot type: two-axis

Empty box storage capacity: 120-150 boxes

The machines have safety doors and sensors to ensure safety

There is communication between machines

A 4-6cm wide adhesive tape can be installed in the box tape mechanism

The machine gives an alert if there is a shortage of boxes, tape or dividers

Required air pressure: 5 - 6 bar

Electricity: 380V, 50-60Hz, 1 phase

The machine is installed on site by our installation team, operating training is provided, and use and maintenance instructions are delivered.

The machines are guaranteed for two years.

Options:

Production with solid coating or all stainless steel

Separator system (carton separator) between products

Automatic box sizing system; Allows quick and automatic transition between different box sizes using servo motors and recipe recording system

Unique designs to suit different product dimensions

Single-head or three-head machines depending on the line capacity