Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

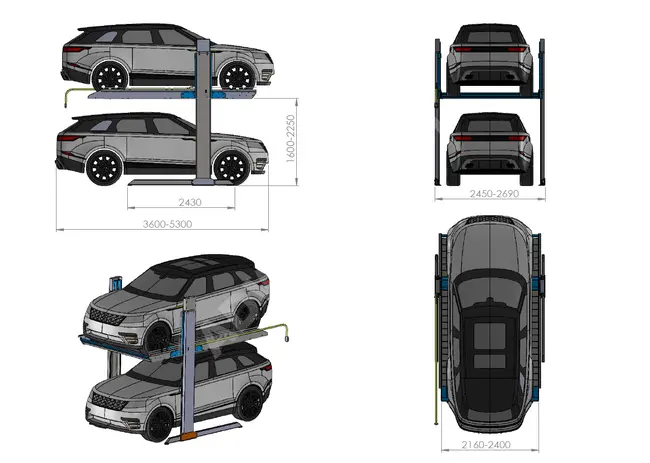

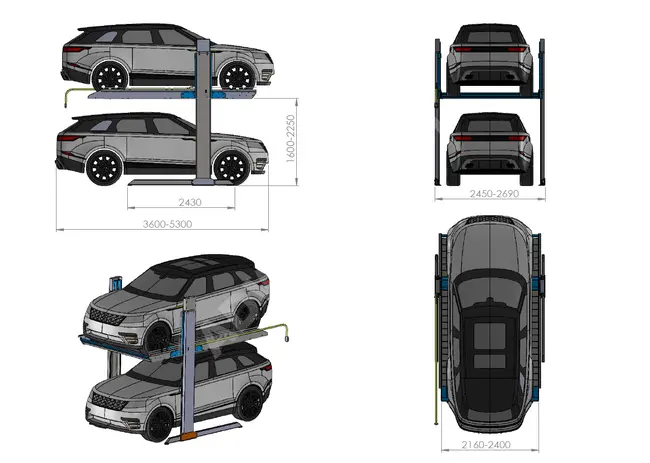

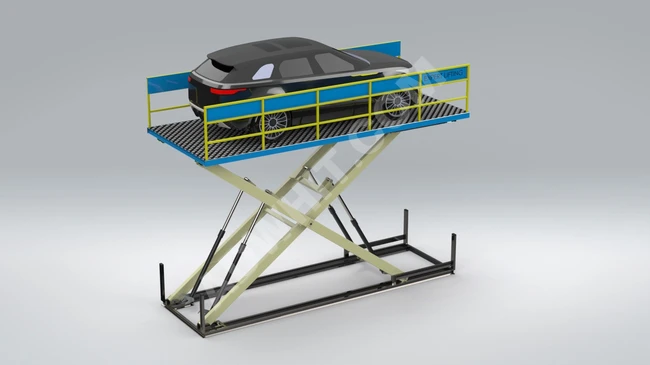

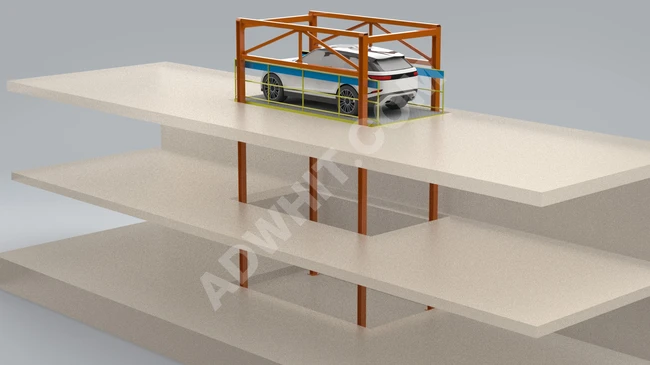

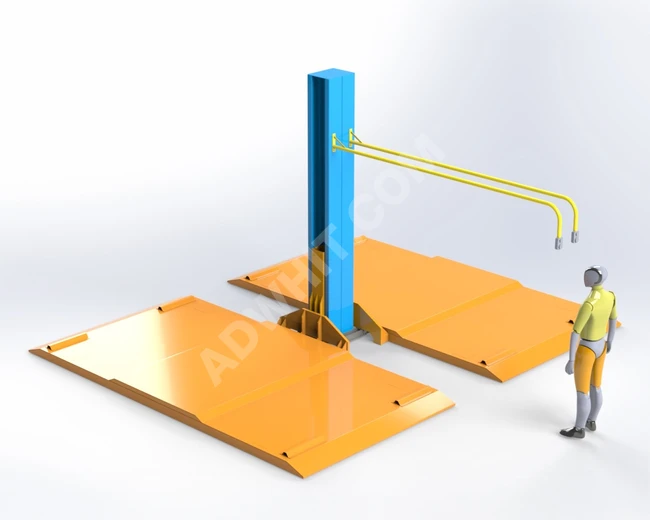

Smart two-post car lift with a capacity of 3500 kg

Enkay SMART2-3500

Smart two column car lift with capacity of 3500kg

CUSTOMIZABLE USE: You can customize the lever according to your own preferences. When you make and save customizations from the user menu, the crane will operate according to the settings you previously defined.

You can set minimum height, maximum height, stop mode, synchronization measurement, etc.

For example: If you work on high cars like a Jeep. You can adjust the lower stop position of the crane upwards for faster loading and unloading.

If you have a low-ceiling work environment, you can set the maximum height to be low.

If you're using it to change tires and only want to work between 0cm and 120cm, you can set the lever to work the way you want with just a few clicks. In short, you can customize the crane as you wish.

Matrix Synchronization System: It is a balancing system exclusive to Enkay Company only. This system has a special balance processing unit designed specifically for this purpose.

The lever operates with a synchronization gap of only 1 cm, making it one of the best systems in the world.

Advanced power management system: The crane runs on three-phase current (industrial electricity) and does not need neutral current, which is rare in the world, making it unaffected by grid neutral power problems.

The crane also measures phase loss, power drops or surges, phase ordering, and protects itself and the operator from potential network faults.

Protecting motors from potential faults is also an element of advanced power management.

All power lines for the crane are supplied by one special cable, eliminating cable clutter.

The crane operates on 24V DC to ensure operator safety in controls and auxiliary devices.

TOUCH SCREEN: The 5-inch touch screen allows you to easily keep track of all lever values and provides interactive ease of use.

Fault information system: The crane is equipped with a system that transmits to the operator 25 different faults, their solutions, and the source of the fault.

User Notification System: The crane is equipped with warning systems to promote effective use by users and to alert potential faults. (Network problems, working status of devices on the crane, distance information of the crane, etc.)

User identification with password: In case you do not want the crane to be used by other people, you can define 4 different types of employees in the system. You can assign a supervisor to the crane and prevent anyone else from using it. You can assign up to 4 users to each crane and track the work of each supervisor or employee.

UI-Friendly Design: The crane has standard screen and buttons to follow all the details and convenient use.

Electronic security system:

The motors that move the crane are operated by relays called contactors. In case of contactors (continuous power flow) sticking, the system detects the problem, stops the uncontrolled movement and informs the operator of the source of the fault. Smart levers electronically move both motors at the same time using sensors. If a problem occurs with any of these sensors, the system stops to protect itself and reports the faulty sensor to the operator.

The hoist has stop switches at minimum and maximum levels. Since the crane moves based on position information, it does not need these switches but they are installed as an additional safety measure to prevent possible accidents.

Double bearing system:

The endless gear shaft is connected to the hoist by double bearings. In this case, the coefficient of friction is significantly reduced in upward or downward motion.

Surveyed lubrication system:

The oil is absorbed into the oil tank by sponge seals. With each movement of the lever, the shaft is lubricated by wiping. Compared with pumped or similar systems, the problems of oil leakage, excessive oil consumption, and insufficient lubrication are eliminated.

Forced lock system - security system:

Your lift operates with a main carriage nut and a second safety nut directly below this nut. Your lift also has a locking system that works with these two nuts. It is one of the rare products that uses a safety nut and locking system. In short, the system moves on the main carrier nut If the main nut wears out over time, the load is transferred to the safety nut The load is now on the safety nut At the same time, your elevator locking system will trip, and it is difficult for the operator to understand this situation, but the load is now on Safety nut. After the repair is complete, the load is lowered down and loaded for a new repair. Once this is completed, the locking system is attached to the lock ring and no movement higher than approximately 10cm is allowed and the system is locked mechanically. The elevator remains in service position mechanically without replacing the main nut and placing the forced locking system in its slot. With this system, upload downloading other than incorrect uploading is definitely prevented. This safety system is one of the main reasons why there have been no examples of elevator falls in Enkay products for over 30 years.

Emergency Stop - Warning Systems: Your elevator has one emergency stop button and one audible warning buzzer. Optionally, additional emergency stop and flashing light plug holes are available and can be installed in addition to your order or later.

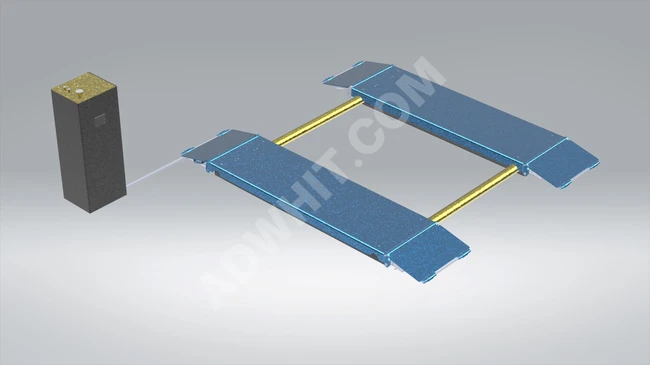

Optional accessories: 5V-24V DC 1 A charging station, battery charging system, fault detection system, undercar lighting system, boom head adapters, ramp system,

Automated Painting: Our elevators are produced in our fully automated painting facility by automated painting using electrostatic powder coating, without human touch. Evenly distributed coating at every point of the lift extends the life of the steel against rust and corrosion and maintains its appearance for a long time against shocks that may come from outside.