Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

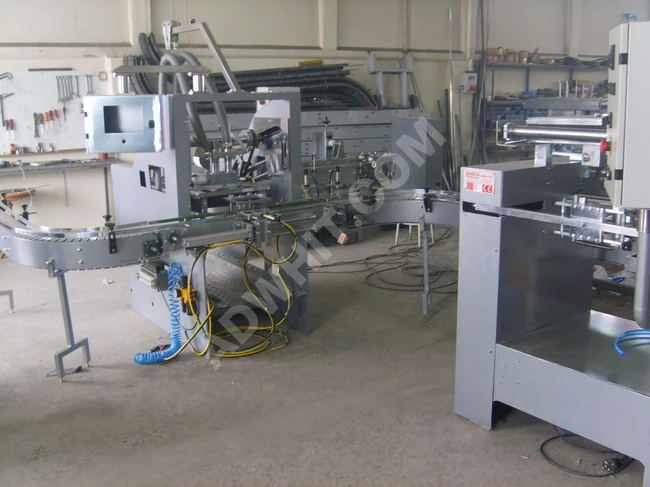

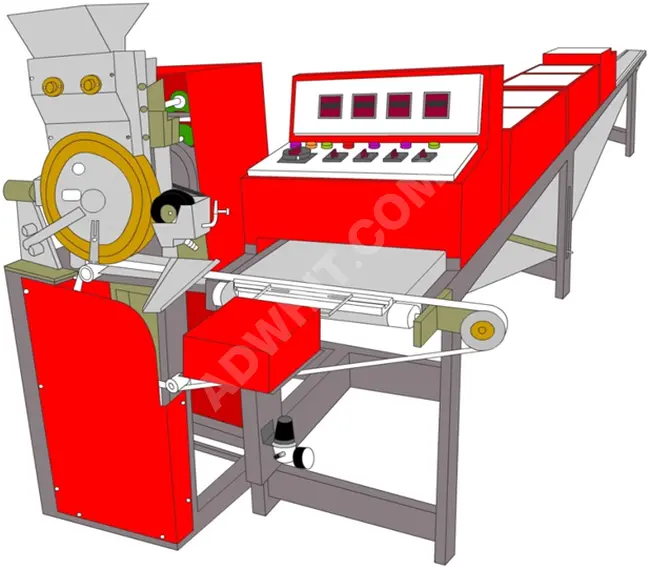

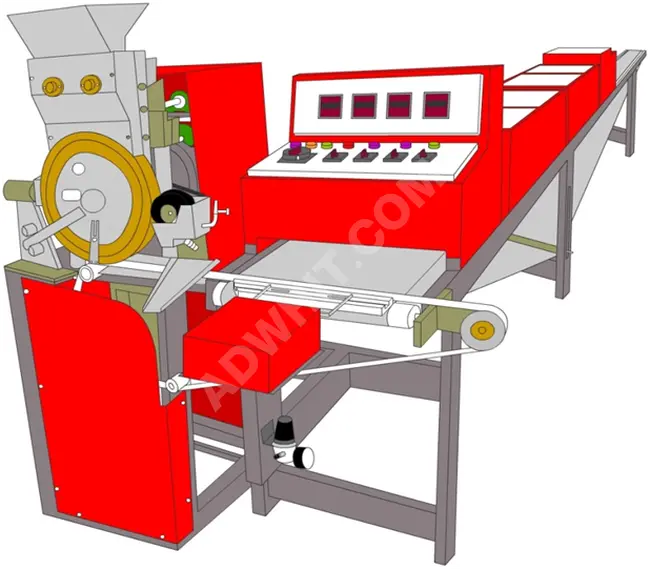

Ready Cup Filling Machine (1500 cups/minute)

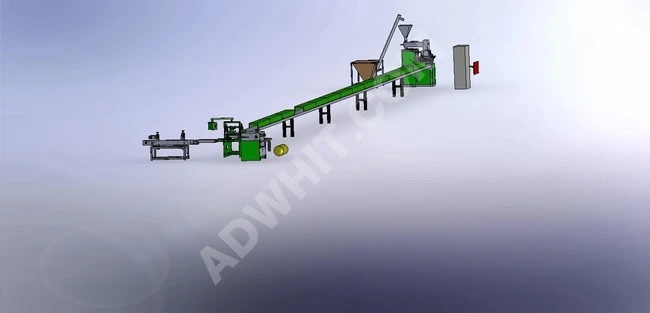

BPH - 2 Linear automatically takes the finished cups placed in the cabinet to the conveyor belt and carries them down the packing group.

In this section, the cups are filled with the required accuracy.

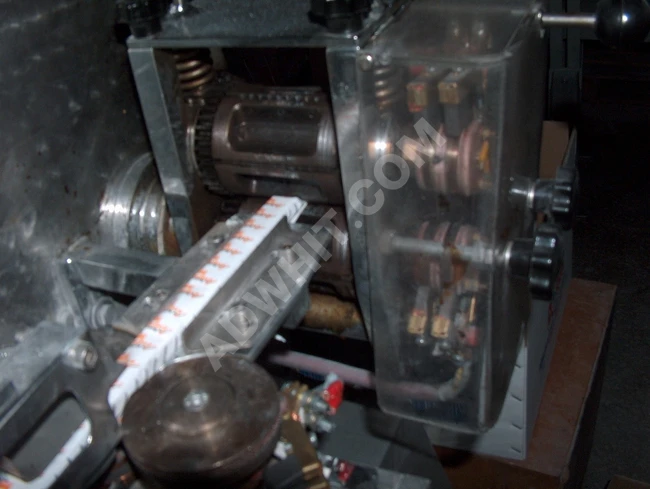

(Depending on the fluidity of the product) Next, the machine automatically places the cups into the gluing and cutting unit, where it glues and cuts the upper foil.

When the process is complete, the machine carries the cups to the capping unit and performs the capping process.

From here, the cups are transferred from the conveyor belt.

It is also possible to use chips printed in BPH -2 Linear.

(Chococream, honey, halva, dairy products (cheese, labneh, cream cheese, etc.))

Technical Specifications ?

Capacity 1000-1500pcs/hour

The body is made of stainless steel (304)

Electricity consumption: 7.5 kW, 50 Hz, 380 volts

Packing capacity max. 1000g

Machine dimensions: 3608 x 1045 x 1740 mm

Maximum weight 500 kg