Property for Sale

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

US Dollar

40.8174

Euro

47.4348

Saudi Riyal

10.8965

Pound Sterling

54.7381

Kuwaiti Dinar

133.3825

United Arab Emirates Dirham

11.1220

Egyptian Pound

0.8409

Iraqi Dinar

0.0312

Bahraini Dinar

108.2604

Qatari Riyal

11.5985

Libyan Dinar

7.5337

Omani Rial

106.1571

Jordanian Dinar

57.5704

Algerian Dinar

0.3142

Moroccan Dirham

4.5143

Syrian Pound

0.0031

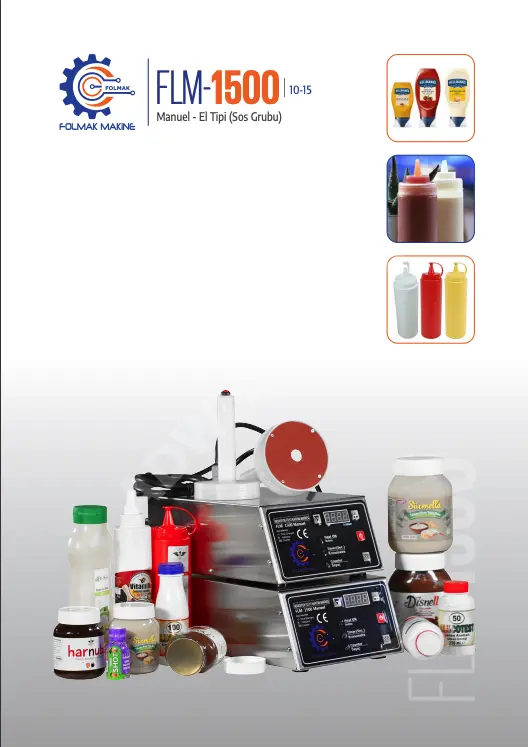

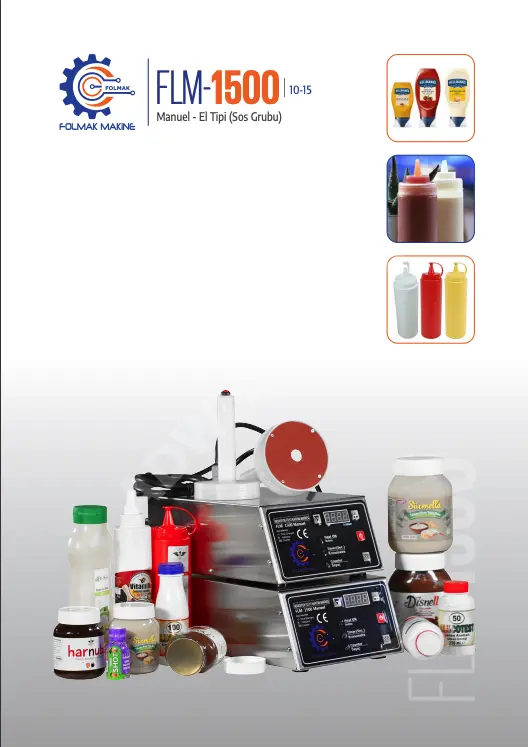

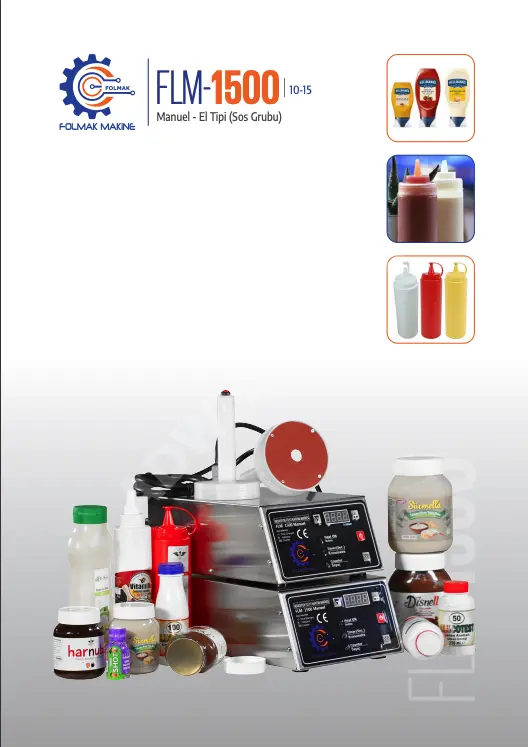

FLM 1500 10 - 15 Manual Aluminum Foil Wrapping Machine for Sauce Type

Bursa / Nilüfer

Status

New

Advertiser

Manufacturer

Brand

Folmak Makine

Details

Address

Bursa / Nilüfer / Beşevler mah.

Offer number

00379860

Offer date

2024/07/04

Communication Languages

FLM 1500 10 - 15 Manual Aluminum Foil Wrapping Machine for Sauce Type

- It is a machine equipped with a tunnel system to ensure the sealing of bottles with special shapes and dropper caps that cannot be sealed with a regular head. Detailed pictures are available below the description.

- It is a machine suitable for simple operation.

- It produces at a rate ranging between 500 – 800 units per hour.

- The production capacity varies according to the diameters of the caps.

- It has a triple capability; it can be sealed with the device, sensor, control button, and manual assistance.

- It features a unique head design that allows comfortable use for different sizes of bottles and caps.

- The entire body and base of the electronic design are made of stainless steel.

- This manual model is designed as a filling unit for low production units.

- It features a design that is easy to carry by hand.

- Laminated aluminum foils with cardboard placed inside the screwable/pluggable plastic caps are sealed onto the package nozzle within one or two seconds after the filling process using induction, providing high-strength sealing. It offers high protection for all solid, liquid, powdered, and granular products presented in plastic or glass containers in all food and other sectors that require nozzle sealing until they reach the end user.

- It provides sealing for all types of bottles, jars, plastic jerrycans, and glass vials using induction foils within approximately two seconds.

- The sealing time can be adjusted using touch buttons (with an accuracy of a tenth of a second).

- It displays the total number of sealed foils on the digital screen.

- Under-cap filling systems provide a barrier against oxygen and moisture in line with the product structure, maintaining the freshness and properties of the products for a long time.

- It is used in the food, pharmaceutical, and industrial sectors.

- Unconditional one-year warranty

- It is a machine suitable for simple operation.

- It produces at a rate ranging between 500 – 800 units per hour.

- The production capacity varies according to the diameters of the caps.

- It has a triple capability; it can be sealed with the device, sensor, control button, and manual assistance.

- It features a unique head design that allows comfortable use for different sizes of bottles and caps.

- The entire body and base of the electronic design are made of stainless steel.

- This manual model is designed as a filling unit for low production units.

- It features a design that is easy to carry by hand.

- Laminated aluminum foils with cardboard placed inside the screwable/pluggable plastic caps are sealed onto the package nozzle within one or two seconds after the filling process using induction, providing high-strength sealing. It offers high protection for all solid, liquid, powdered, and granular products presented in plastic or glass containers in all food and other sectors that require nozzle sealing until they reach the end user.

- It provides sealing for all types of bottles, jars, plastic jerrycans, and glass vials using induction foils within approximately two seconds.

- The sealing time can be adjusted using touch buttons (with an accuracy of a tenth of a second).

- It displays the total number of sealed foils on the digital screen.

- Under-cap filling systems provide a barrier against oxygen and moisture in line with the product structure, maintaining the freshness and properties of the products for a long time.

- It is used in the food, pharmaceutical, and industrial sectors.

- Unconditional one-year warranty

Similar offers

Creating your own product (brand): Choose the product design and we will handle the manufacturing.

8

TL

New

Manufacturer

Başakşehir, İstanbul

2025/04/17

Volumetric Solid Filling Machine (in bags)

0

TL

New

Manufacturer

Esenyurt, İstanbul

2025/04/10

Solid materials filling machine with weighing system (in bags)

0

TL

New

Manufacturer

Esenyurt, İstanbul

2025/03/07

Solid materials packing machine in weight-based system

1

TL

New

Manufacturer

Esenyurt, İstanbul

2025/02/26

Thermoforming Packaging Machine

1

TL

New

Manufacturer

Esenyurt, İstanbul

2025/02/21

Carton Filling Machine

0

TL

New

Manufacturer

Esenyurt, İstanbul

2025/02/15