Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

Car rim straightening machine with digital control (NC) for sizes 10''-30''

Car rim adjustment machine

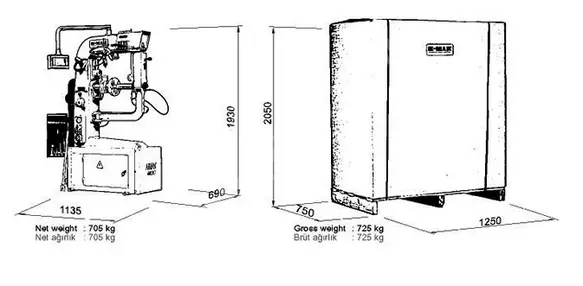

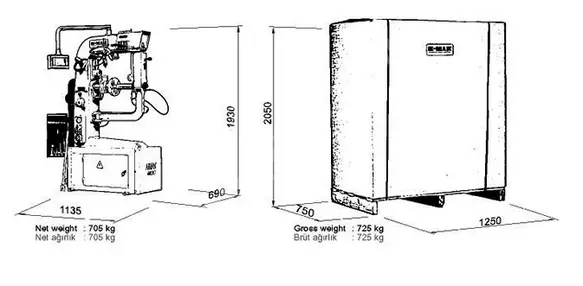

Technical specifications of Micro 10"-30 machine:

- Maximum diameter of rims: 10”-30”

- Maximum width of rims: 12''

- Hydraulic motor power: 0.75 kW, 380 V, 50 Hz, three-phase

- Spindle motor: 100 HP/100 RPM, 0.75 kW, 24 V-DC with brake and reducer

- Operating pressure: 0-175 bar (standard 150 bar)

- Sound intensity: 70 decibels

- Color: RAL 7011 gray - RAL 3000 red

Product Description:

Our machine is designed to correct rims ranging from 10” to 30”.

It is possible to intervene in all areas of the rims of private cars and light commercial vehicles.

It features a motor with reducer and brake to automatically stabilize the rim during the correction process.

Thanks to its special design, any balance operator in wheel and tire repair shops can easily learn to use it.

It identifies the defective area with 360° accuracy with a peripheral sensitivity and error of 0.05 mm, and displays the information on the touch screen.

After that, the reference points (+) and (-) are placed precisely under the piston to make the correction.

Quality inspection is performed by computer, ensuring that quality inspection is not left to the discretion of the operator.

The Micro 10” 30” machine can be combined with an optional base lathe 10” 30” lathe machine to correct damaged rim edges after the adjustment process.

The machine is delivered with a set of standard accessories that include rim adjustment bushes for different sizes, piston extension rods, rim mounting kit, correction heads and a lever.