Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

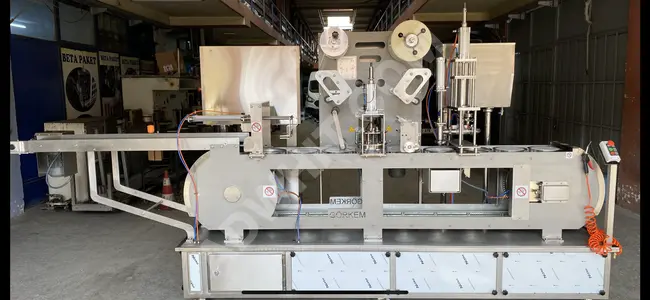

Linear Filling Line Conveyor System

Feeding tray

Technical Specifications

- **Diverse dimensions**

- **Construction**: AISI 304 stainless steel

- **Speed adjustable asynchronous motor**

-Air bottle cleaning machine

Technical Specifications

- **Construction**: AISI 304 stainless steel construction

- **Number of nozzles**: 2-120,

With 0.2 micron filter and ionizer

- **Control system**: Easy-to-use PLC control system

- **Touch operation panel**

- **Windows equipped with safety switches**

- **Easy to clean mesh belt**

- **Unlimited recipes**

Linear packaging machine with conveyor system

Technical Specifications

-**System**: Linear

- **Filling system**: Volumetric / flow meter / load cell / level control

- **Construction**: AISI 304 stainless steel body, AISI 316L stainless steel product contact surfaces

- **Balance Tank**: Control the C.I.P. level. collective

- **Number of nozzles**: 1-12

- **Filling range**: 20-300ml / 100-1000ml / 250-2500ml / 500-5000ml / 2000-20000ml

- **Filling accuracy**: ± 0.3%

- **Electricity requirements**: 380V, 50Hz, 3 phase

- **Air requirement**: 6-8 bar

- **Capacity**: Varies depending on the shape of the bottle, the number of nozzles, and the viscosity of the product

- **Various packing methods depending on the product**

- **Filling feature from the bottom and from the top**

- **FDA approved silicone hose**

- **Easy to clean filling tanks**

- **Tri-Clamp Quick Connection**

- **Volume filling system with servo control, speed and weight adjustable from the screen**

- **Nozzle movement with servo control, adjustable speed and location from the screen**

- **Easy to use PLC control system**

- **Touch operation panel**

- **Unlimited recipes**

- **Entry and exit line full sensors**

- **Windows equipped with safety switches**

- **Easy to clean mesh belt**

Lid closing machine

Technical Specifications

- **System**: Rotary / on conveyor

- **Construction**: AISI 304 stainless steel body, AISI 316 stainless steel product contact surfaces

- **Lids Closure System**: Clamp / Three-Ball System / Pick&Place / Straight Press / Twist / Press

- **Lids closing drive system**: Servo torque / Asynchronous motor / Mechanical torque / Pneumatic motor

- **Casing feeder**: Elevator / Vibrating bowl / Drum

- **Lid feeding system varies depending on the lid**

- **Electricity requirements**: 380V, 50Hz, 3 phase

- **Air requirement**: 6-8 bar

- **Various closing methods depending on the product**

- **Easy to use PLC control system**

- **Touch operation panel**

- **Unlimited recipes**

- **Windows equipped with safety switches**

- **Entry and exit line full sensors**

- **Easy to clean mesh belt**

Labeling machine

Technical Specifications

- **System**: Full wrap labeling / Single side labeling / Double side labeling / Top labeling

- **Construction**: AISI 304 stainless steel construction

- **Distributor**: Local/imported

- **Electricity requirements**: 220V, 50Hz, 1 phase

- **Different methods of applying labels depending on the product**

- **Easy to use PLC control system**

- **Touch operation panel**

- **Unlimited recipes**

- **Easy to clean mesh belt**

Technical Specifications

Different dimensions

Construction: AISI 304 stainless steel

Speed adjustable asynchronous motor

- Medicines, food, cosmetics and chemistry