Property for Sale

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

US Dollar

38.4456

Euro

43.7336

Saudi Riyal

10.2610

Pound Sterling

51.3408

Kuwaiti Dinar

125.5394

United Arab Emirates Dirham

10.4680

Egyptian Pound

0.7569

Iraqi Dinar

0.0293

Bahraini Dinar

102.0264

Qatari Riyal

10.9420

Libyan Dinar

7.0252

Omani Rial

99.8613

Jordanian Dinar

54.2098

Algerian Dinar

0.2893

Moroccan Dirham

4.1448

Syrian Pound

0.0030

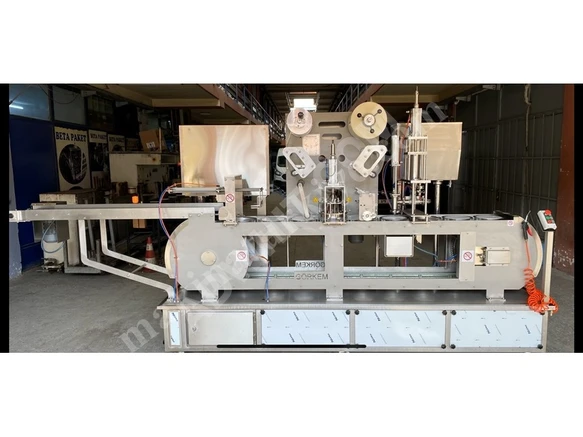

Foil wrapping machine 800-900 units/hour

İstanbul / Zeytinburnu

Status

New

Advertiser

Manufacturer

Brand

Görkem Makina

Details

Address

İstanbul / Zeytinburnu / Maltepe mah.

Offer number

00379864

Offer date

2024/07/04

Communication Languages

Foil wrapping machine 800-900 units/hour

• The materials used are 304-grade stainless steel. (Including the transmission body and chains)

• The foil coil set is controlled by 3 independent reducers.

• The foil is heat-sealed and cut with an appropriate knife.

• The capacity of the cream cheese and margarine filling and sealing machine is 800-900 units/hour for a maximum weight of 200 grams.

• The machine is controlled by a Panasonic PLC, which facilitates machine intervention through the color screen.

• Since the cream cheese and margarine filling and sealing machine is equipped with speed control (with a frequency converter), the operator can work at the most suitable speed.

• In filling these types of high-viscosity products, a volumetric filling system (suction and volumetric pressure) is used. The filling system can be set according to the required weight and installed next to the machine.

• Safety measures are the same as in the double yogurt filling machine

• The foil coil set is controlled by 3 independent reducers.

• The foil is heat-sealed and cut with an appropriate knife.

• The capacity of the cream cheese and margarine filling and sealing machine is 800-900 units/hour for a maximum weight of 200 grams.

• The machine is controlled by a Panasonic PLC, which facilitates machine intervention through the color screen.

• Since the cream cheese and margarine filling and sealing machine is equipped with speed control (with a frequency converter), the operator can work at the most suitable speed.

• In filling these types of high-viscosity products, a volumetric filling system (suction and volumetric pressure) is used. The filling system can be set according to the required weight and installed next to the machine.

• Safety measures are the same as in the double yogurt filling machine

Advertiser Information

Gorkem Ltd. for the Manufacturing and Trading of Hardware Machinery

Görkem Makina

Similar offers

Creating your own product (brand): Choose the product design and we will handle the manufacturing.

8

TL

New

Manufacturer

Başakşehir, İstanbul

2025/04/17

Water and juice filling machines

0

TL

New

Manufacturer

Başakşehir, İstanbul

2025/01/31

Powder filling machine in bags

100

TL

New

Manufacturer

Esenyurt, İstanbul

2025/02/13

Volumetric Solid Filling Machine (in bags)

0

TL

New

Manufacturer

Esenyurt, İstanbul

2025/04/10

Solid materials packing machine in weight-based system

1

TL

New

Manufacturer

Esenyurt, İstanbul

2025/02/26

Solid materials filling machine with weighing system (in bags)

0

TL

New

Manufacturer

Esenyurt, İstanbul

2025/03/07