Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

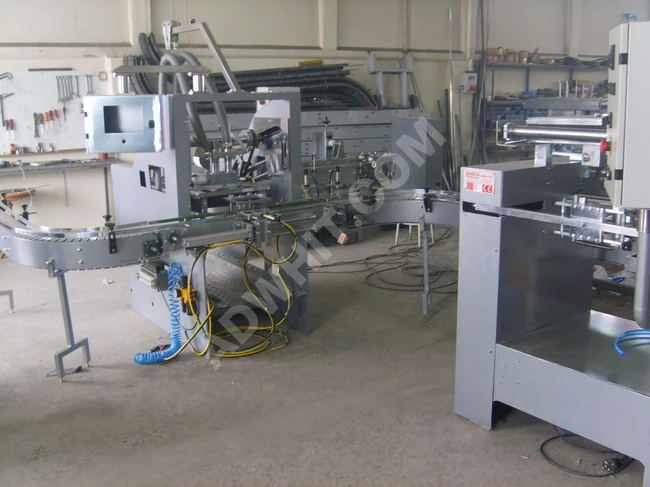

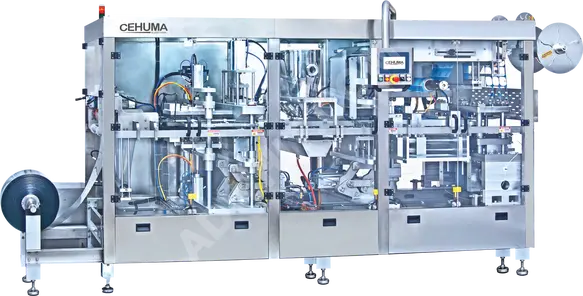

Thermal Cup Forming Machine / Fruit Juice Cup Machine

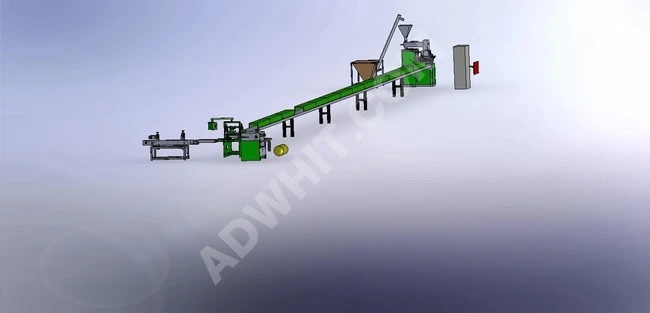

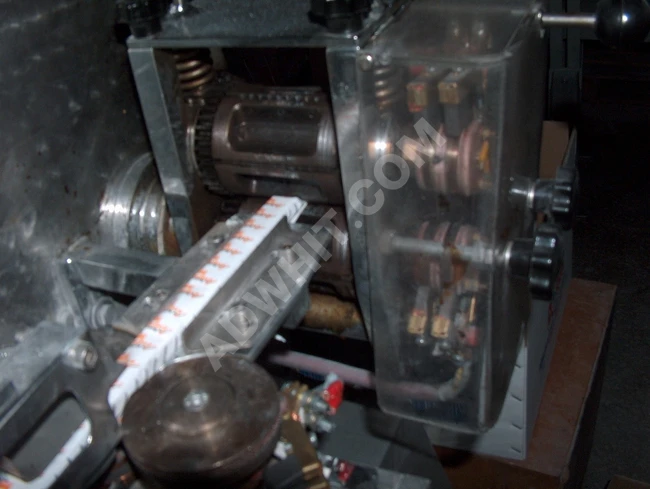

YZ thermoforming machines are mainly for automatic filling and sealing applications, often used for water, juices, ketchup, mayonnaise, honey, jam, chocolate paste, hazelnut paste, cream cheese, coffee, milk, yogurt... The machine is used for filling and sealing. It is a cam driven machine; Which means that the forward movement of the plastic film is done by a mechanical cam system that provides extremely high performance up to 35 revolutions per minute.

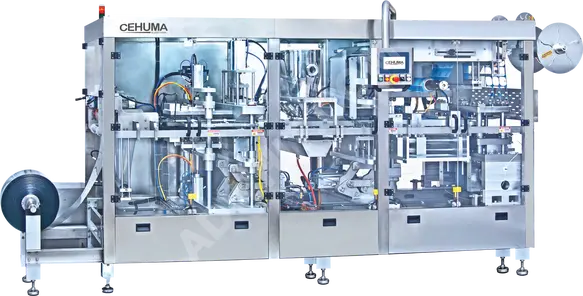

Also known as horizontal thermoforming filling and sealing machines, Cehuma's YZ series is very suitable for automatic filling of water, juice, carbonated and non-carbonated drinks, mineral water, salt water, etc.

Since packaging design is as important as the product itself, Cehuma offers a wide range of attractive and funky designs that will make your products stand out on store shelves and put you a step ahead of your competitors.

In HFFS machines, hygienic packaging is one of the most important aspects that Cehuma focuses on in every project. Cehuma's YZ Series horizontal fill and seal machines feature extremely smooth surfaces in the fill units that prevent the growth of microbial particles, making the product safer than ever.

We also offer our customers a complete solution that includes end-of-line robots to carton, wrap, and shrink each product ready for shipping.

In packaging water cups or other similar products, it is common to use PET films or similar on the bottom and aluminum foil on the top.

Technical Specifications

Capacity (beats/minute) | 15-35

Cursor (step) (mm) | 70-200

Bottom film width (mm) | 150-500

Bottom film thickness (m) | 550-1200

Bottom film material | PVC/PET/PS/PP

Upper film material | AL+PET

Machine length (mm) | 5,500-11,000

Power consumption (kW) | 8-25

Electricity supply 3x380V. 50 Hz.

Compressed air requirement (bar) | 6-8

Cooling water (°C) | 10-16

Features Stainless steel construction

Servo technology

Safety standards according to EC regulations

Wide packaging design options

Programmable advance speed

Large touch screen

Multiple language options

Precise doses

Advanced cutting/punching technology