Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

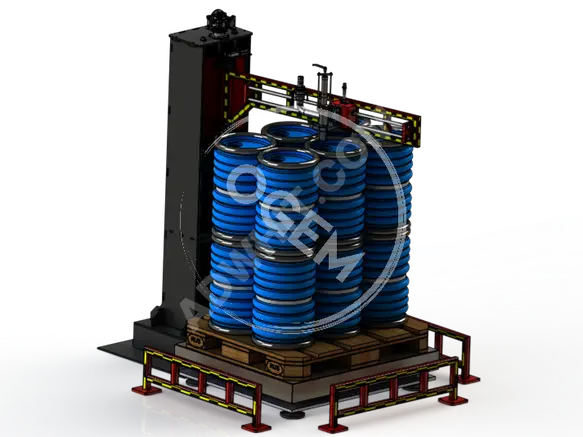

Semi-automatic filling machine with a single nozzle for filling containers with a weight of 200-2000 kg

Technical Specifications

✓ Number of filling nozzles in the machine: 1

✓ The machine works with a pneumatic weighing filling system.

✓ Operating system: mechanical, pneumatic, and electrical control.

✓ Adjust weight from 200kg to 2000kg.

✓ It takes the product to be filled directly from the production tank by means of a pump.

✓ The nozzle and filling line are designed for easy cleaning.

✓ The machine requires 8 atmospheres of air (air compressor) and 380 volts of electrical power to operate.

✓ Machine-mounted pneumatic manual cap closing device is available upon request.

✓ All surfaces in contact with the product are made of chemically resistant PVC (polyvinyl chloride) or AISI 316 depending on product characteristics.

✓ It is easy to adjust the weight of the machine via PLC screen.

✓ Nozzles can be easily adjusted to suit different bottle sizes.

✓ It has a tip closing mechanism, which prevents drip and keeps the bottles clean.

✓ It has the advantage of fast filling at the beginning and slow filling towards the end to achieve precise filling.

Areas of use

Chemistry and cosmetics:

Liquid detergents, liquid hand soaps, softeners, liquid dish detergents, acid detergents, laundry bleach, liquid fertilizers, all chemical and cosmetic products packed in buckets, drums, and metal cans from 5 kg to 50 kg.

Mineral oils:

Engine oil, fuel additives, antifreeze, all mineral oils.

Paints:

Paints, all paint industry products packed in buckets, drums, and metal cans from 5 kg to 50 kg.

Number of packing capacity

Filling machine capacity varies depending on operator and product chemical properties (e.g. foam)