Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

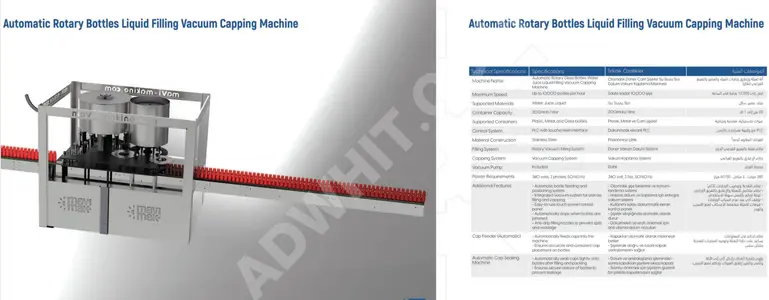

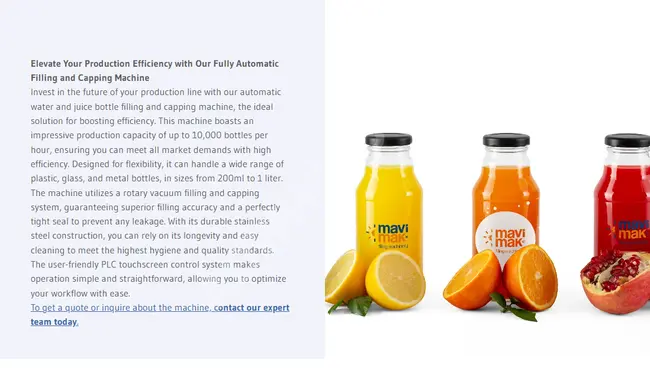

Rotary filling machine with conveyor system

Technical Specifications

System: rotary

Filling system: volumetric / flow meter / load cell / level control

Construction: AISI 304 stainless steel body, AISI 316L stainless steel product contact surfaces

Balance tank: level control C.I.P. collective

Number of nozzles: 1-4

Filling range: 20-300ml / 100-1000ml / 250-2500ml

Filling accuracy: ±0.3%

Lid closing system: catch/three-ball system/pick and place/straight squeeze/twist/push

Caps closing operating system: servo torque / asynchronous motor / mechanical torque / pneumatic motor Caps feeding: elevator / vibrating bowl / cylindrical

The cap feeding system changes depending on the cap.

Electricity requirements: 380V, 50Hz, 3 phase

Air requirement: 6-8 bar

Capacity: varies depending on the shape of the bottle, the number of nozzles and the viscosity of the product.

Various packing methods depending on the product

Bottom and top filling feature

FDA approved silicone product hose

Easy-to-clean filling tanks

Tri-Clamp quick connect

Servo-controlled volumetric filling system whose speed and weight can be adjusted from the screen

Servo-controlled nozzle movement whose speed and position can be adjusted from the screen

User-friendly and advanced PLC control system

Touch operation panel and unlimited recipes

Blocked linear sensors for input and output

Windows with safety key

Easy to clean mesh belt