Property for Sale

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

US Dollar

38.0180

Euro

41.8354

Saudi Riyal

10.1304

Pound Sterling

48.6738

Kuwaiti Dinar

124.0626

United Arab Emirates Dirham

10.3494

Egyptian Pound

0.7398

Iraqi Dinar

0.0290

Bahraini Dinar

100.8435

Qatari Riyal

10.7650

Libyan Dinar

7.8902

Omani Rial

98.7532

Jordanian Dinar

53.6296

Algerian Dinar

0.2837

Moroccan Dirham

3.9811

Syrian Pound

0.0029

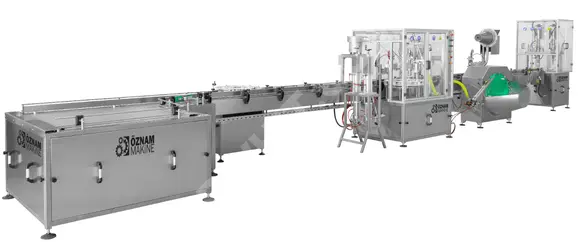

OZ-TOD-20 - Automatic Aerosol Filling Machine

İstanbul / Başakşehir

Status

New

Advertiser

Manufacturer

Brand

Öznam Makina

Details

Address

İstanbul / Başakşehir / Ziya gökalp mah.

Offer number

00379613

Offer date

2024/06/25

Communication Languages

OZ-TOD-20 - Automatic Aerosol Filling Machine

Product Code: OZ-TOD-200

In the automatic machine, some applications are performed manually. The applications that are performed manually are closing the lids and installing the valves. The cans coming from the conveyor enter the liquid filling process as the first step. After manually installing the valves, the cans pass through the valve fixing stage and then proceed to the gas filling process. The can heads are automatically fixed after they exit the gas filling, then the lids are closed manually, and the products become ready for packaging after the inkjet printing unit.

Technical Specifications of the Product:

- Gas Pressure: 8 bar

- Air Pressure: 8-10 bar

- Production Capacity: 50-60 cans (with a capacity of 200 ml)

- Maximum Gas Filling Capacity: 400 grams

- Air Consumption: 3500 liters/minute

- Approximate Length: 11.5 meters

- Electrical Specifications: 220 volts – 3 kilowatts

In the automatic machine, some applications are performed manually. The applications that are performed manually are closing the lids and installing the valves. The cans coming from the conveyor enter the liquid filling process as the first step. After manually installing the valves, the cans pass through the valve fixing stage and then proceed to the gas filling process. The can heads are automatically fixed after they exit the gas filling, then the lids are closed manually, and the products become ready for packaging after the inkjet printing unit.

Technical Specifications of the Product:

- Gas Pressure: 8 bar

- Air Pressure: 8-10 bar

- Production Capacity: 50-60 cans (with a capacity of 200 ml)

- Maximum Gas Filling Capacity: 400 grams

- Air Consumption: 3500 liters/minute

- Approximate Length: 11.5 meters

- Electrical Specifications: 220 volts – 3 kilowatts

Similar offers

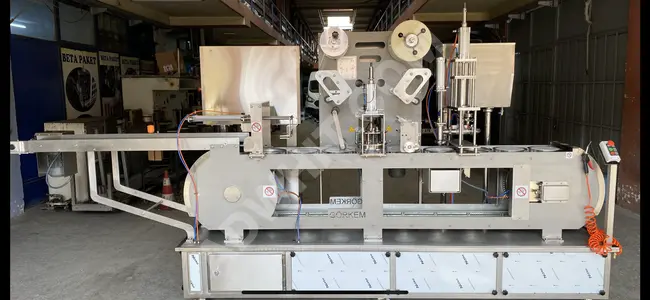

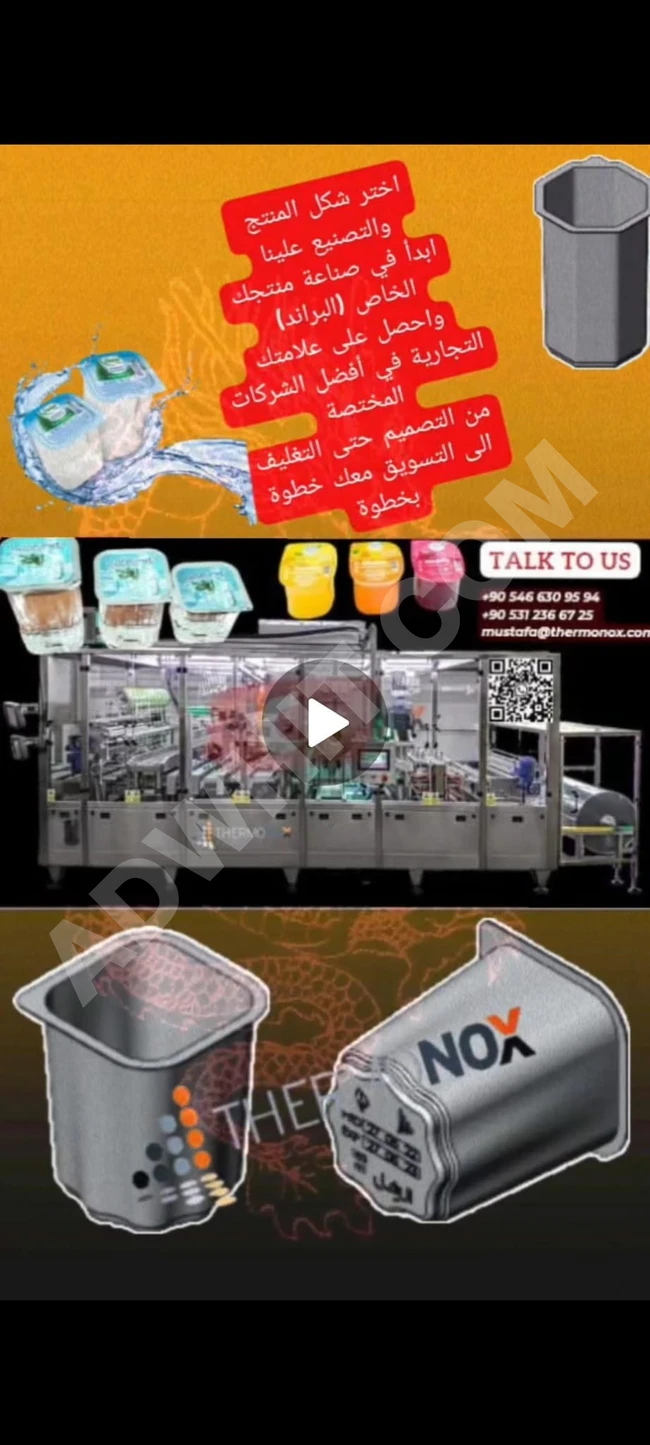

6-lane cream cheese filling machine

0

TL

New

Owner

Başakşehir, İstanbul

2025/01/23

Two-lane cream cheese filling machine.

0

TL

New

Owner

Başakşehir, İstanbul

2025/01/23

Automatic foil (aluminum foil) cutting and pasting machine.

0

TL

New

Owner

Başakşehir, İstanbul

2025/01/23

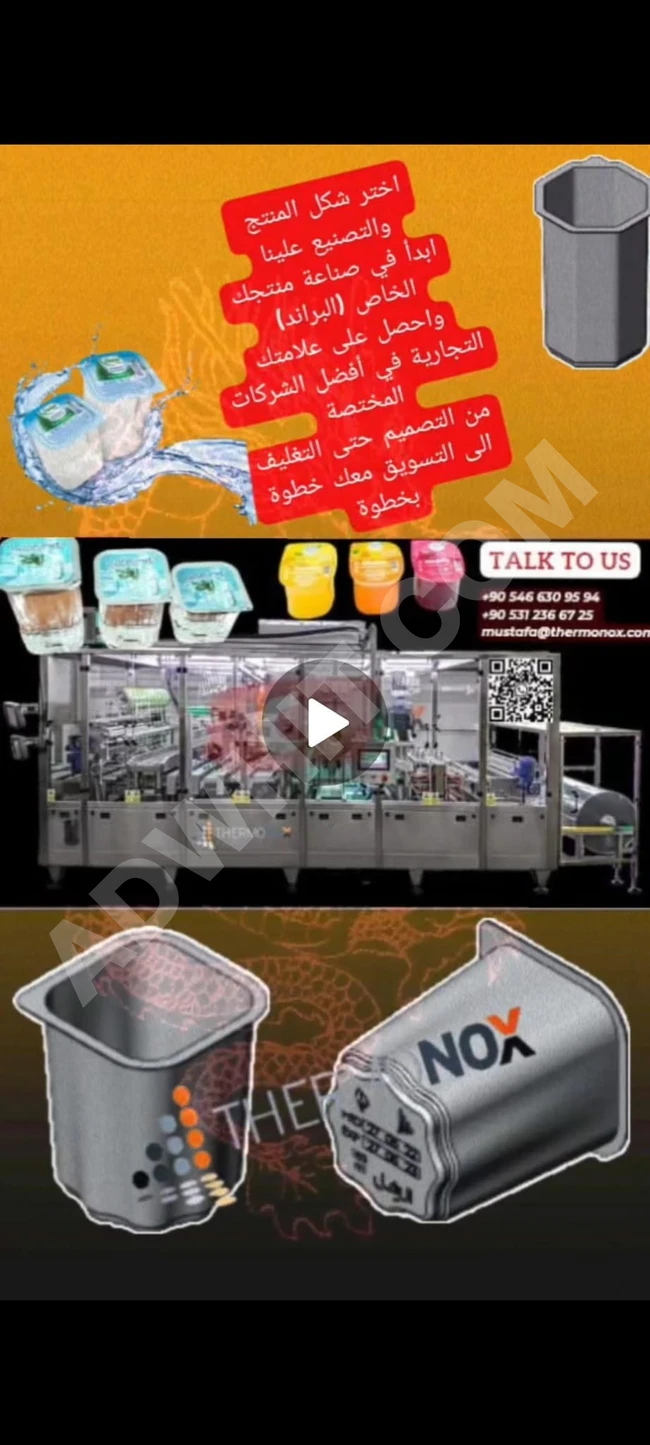

Water and juice filling machines

0

TL

New

Manufacturer

Başakşehir, İstanbul

2025/01/31

Perceived Quality 👌👇/ Brand Management

0

TL

New

Manufacturer

Başakşehir, İstanbul

2025/01/08

Powder filling machine in bags

100

TL

New

Manufacturer

Esenyurt, İstanbul

2025/02/13