Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

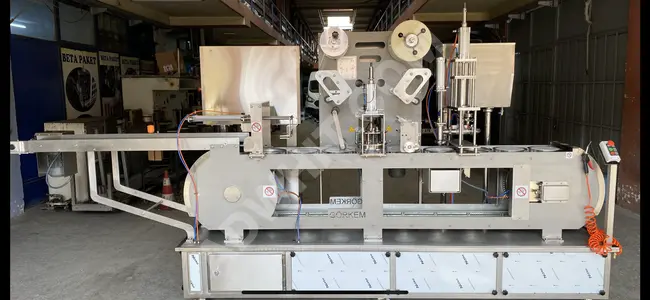

Olive oil filling machine 100-1000 ml

Olive oil filling and covering machine 100-1000 ml

It is a machine that automates the processes of filling and covering olive oil within a variable weight range in industrial production processes. It allows you to carry out filling operations, closing lids, and placing labels on all types of containers (plastic, glass, tin) without problems. The filling system and nozzle groups are digitally controlled by a servo control system. The caps are automatically fed according to three types of caps (compression cap, screw cap, aluminum cap) on the conveyor, and it performs the operations of feeding and pressing the caps, closing the aluminum caps with four Italian origin discs, and closing the screw caps with torque. After filling and closing the lids, the Herma two-way labeling machine applies the labels to the packages.

Technical specifications of the filling machine:

Packing set: 304 quality stainless steel

Sealing elements: PTFE TEFLON and VITON

Control systems: Touch screen and electro-pneumatic system (LG PLC and LG 10-inch touch screen + Pemaks pneumatic system)

Language options: Turkish and English

Inhibitor: Bottom and top filling system to prevent foaming, nozzle system (8 heads) manufactured upon request.

Filling system: servo control

Volume: 100ml – 1000ml (2400 units/3000 units/hour)

Control voltage: 24V DC

Operating voltage: 380V 50Hz 10A

Energy consumption: 1.5 kW/h

Body: 1200 x 1200 quality 304 stainless steel

Conveyor: (3 meters acetal sheet)

Protection chambers: Plexiglass covering on 304 quality body (for filling and sealing)

Lid closing machine:

Body: 304 quality stainless steel

Carrier plate: (3 meters acetal sheet)

Conveyor motor: 380V 0.37kW (S40/21)

Energy consumption: 1.5 kW/h

Closing of caps: feeding caps on the conveyor, closing screw caps with torque, closing aluminum caps with four discs of Italian origin

Bottle Holder Star: It will be set up for model bottles

Herma complete labeling machine (circular roll and double-sided labeling):

Pulley diameter: 75mm

Label width: 10-160mm

Label length: 10-300mm

Label exit speed: 5-15m/min

Number of labels: 3000-4000 units/hour

Control system: PLC control

Unit: 2 step unit 240V

Operating voltage: 220V 50Hz 12A

Control voltage: 24V DC

Label sensors: Possibility of working with transparent and opaque labels

Start Label: Reflective Optical Sensors

Bottle winding belt: 0.18 kW S30 I15

Upper pressure belt: 0.18 kW S30 I15

Bottle correction belt: 3PH 12.5B

Bottle separator motor: 0.18 kW S30 I60

Body: 304 quality stainless steel

Conveyor and winding motor: 380V 0.37kW (S40/21)

Energy consumption: 1 kW/h