Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

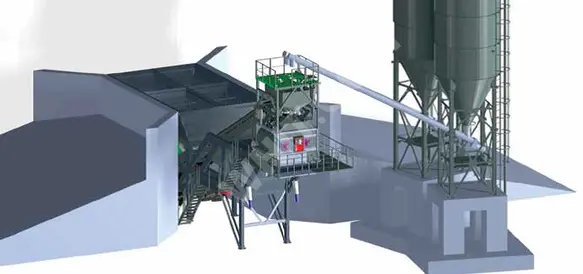

MRM 100M Mobile Ready-Mix Concrete Plant

Laboratory/factory/concrete/concrete production station MRM 100M mobile concrete

A concrete plant (in English: Concrete Plant or Batching Plant) is an equipment that mixes several components to produce concrete, including: water, air, chemicals, sand, gravel (rock, gravel, etc.), fly ash, silica dust, slag, and cement. The concrete plant consists of several units, parts, and accessories, such as: cement mixer, cement silos, component silos, conveyor belts, heaters, refrigerators, dust collectors, controllers, and others.

Production efficiency:

With a 1 m³ plant type mixer, the production capacity is 60 m³

Ease of transportation:

Only one transport truck

Easy and quick construction and installation:

Only within a period ranging between 4-5 days

Technical characteristics:

Production capacity per hour: 80-90 m³/hour

Mixer capacity: 2 m³ (2000/3000 litres)

Mixer Type: MRM Dual Horizontal Shaft (TWIN SHAFT)

Mixer motor capacity: 37X2 kW

Aggregate container capacity: 15X4 m³ = 60 m³

Aggregate container type: square in shape

A safe weighing rubble: 4400 kilograms

Conveyor belt feeding the mixer: 10 x 800 x 12,000 mm

Cement safe: 1000 kilograms

Water tank capacity: 700 litres

Tank weighing additional active ingredients: 50 litres

Automatic control system: Schneider/Siemens

Plant mixing and scraping: Sfero

Mixing and scraping shovels: Ni-Hard 4

Non-corrosive sidewall layers: 10 mm Hardox

Non-corrosive base layer: 18mm Ni-Hard 4

Total station capacity: 125 kW