Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

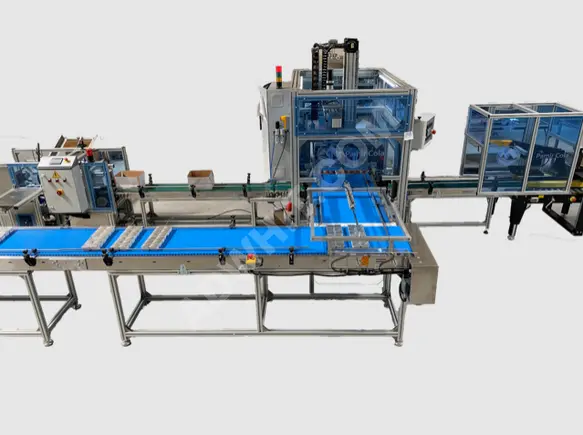

Fully automatic box filling machine with a single head

The products come from the production line to the fully automatic carton packing robot and are assembled in the required quantity.

The products are placed into the cartons coming from the fully automatic carton preparation machine using a vacuum suction system or a grip (grasp and squeeze) system inside the carton. Upon request, the product can be placed in more than one layer in the carton and a carton separator (separator) can be installed.

The packed cartons are sealed in the fully automatic carton sealing and wrapping machine by closing the top covers and wrapping them with tape.

In this way, the filling process is done without touching. The robot section contains two servo motors.

Speed control motors and PLC touch screen operator are used.

Thanks to the screen, all commands can be followed.

Thanks to the servo motor, filling is done very quickly.

In addition, the robot moves aesthetically and suspensefully.

In this way, the robot operates without feeling the forward, backward, up and down movements it makes.

It increases the efficiency of plant production capacity and reduces staff costs, and our patented system is suitable for all sectors.

Our machine consists of 3 main sections;

In the first section, the robot creates the carton automatically.

In the second section, the robot automatically packs the products into the carton.

In the third section, the robot automatically wraps the carton until it is ready for packing.

Optional equipment:

Carton separator placement system (separator)

Changeable product holder for packing different types and sizes of products in one machine

Auxiliary equipment:

Fully automatic bottom carton opening, preparation and packaging machine

Fully automatic carton top cover sealing and sealing machine

Intermediate conveyor belts and exit conveyor belts