Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

Fully Automatic Baler MBS-150LIK

Technical specifications and materials used

The bale size measures 125 x 115

The pressure chamber measures 125 x 180 x 115

The duration of pressing is 30 seconds

The pressure force of the rear piston cylinder is 150 tons

The number of wires in the bale is 5 wires. The splicing is done completely automatically

The working mechanism of the electric press is fully automatic

Electric motor capacity: 55 kW, 2 GAMAK/VALT

The compression force ranges from 200 to 280 bar

Production capacity is 16 tons per hour per carton

The weight of a cardboard bale of size 180 x 125 x 115 ranges from 1250---1500 kilograms.

The press will be equipped with a plastic shredder with a motor capacity of 2.2 kW, number 2

Production capacity of PET plastic: 12 tons per hour

The weight of the PET plastic bale with size 115 x 125 x 180 ranges from 600---750 kilograms.

The piston floor is made of 30 mm sheet thickness

The piston side frame and upper ends are made of 25 mm ST52 sheet thickness

A metal conveyor belt 16 meters long and 180 cm wide in the shape of the letter Z will be added

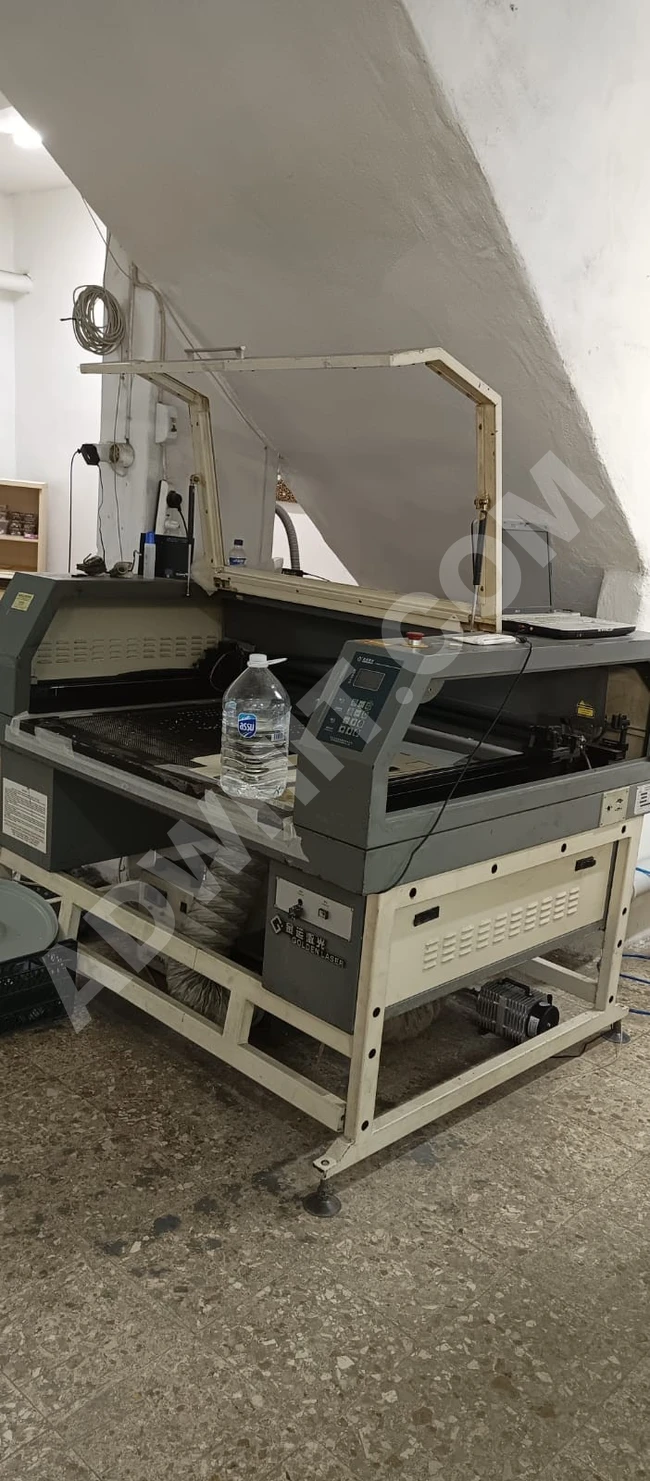

The metal chain of conveyor belt is split by laser cutting machine into 6mm thickness

The conveyor belt works with high-quality metal frames

Approximate total weight of the press: 25 tons

The material unloading room will be provided with an upper balcony

The height of the unloading chamber from the ground is 4 metres

Hydraulic oil cooling device, 220 liters, 2 pieces

The electrical panel is equipped with a FATEK-SİMENS PLC self-control system

The electrical panel control screen is in Arabic

Japanese KAWASAKİ hydraulic pump 140 + 200 CC