Property for Sale

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

US Dollar

38.0090

Euro

41.7488

Saudi Riyal

10.1362

Pound Sterling

48.7111

Kuwaiti Dinar

123.6357

United Arab Emirates Dirham

10.3484

Egyptian Pound

0.7414

Iraqi Dinar

0.0290

Bahraini Dinar

100.8384

Qatari Riyal

10.4448

Libyan Dinar

6.8485

Omani Rial

98.7324

Jordanian Dinar

53.6169

Algerian Dinar

0.2835

Moroccan Dirham

3.9886

Syrian Pound

0.0029

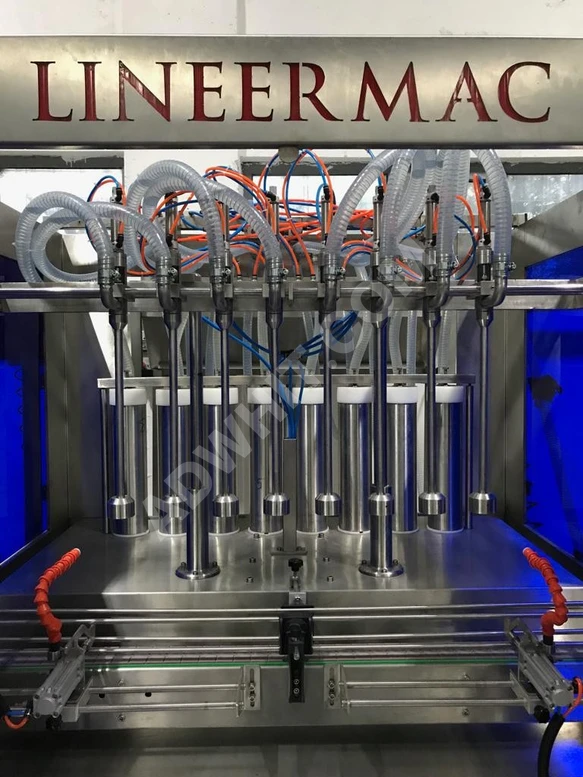

Filling and Capping Machine with 8 Nozzles

1,577,725.80 TL

İstanbul / Esenyurt

Status

New

Advertiser

Manufacturer

Year

2024

Details

Address

İstanbul / Esenyurt / Osmangazi mah.

Offer number

00376756

Offer date

2024/02/15

Communication Languages

Filling and Capping Machine with 8 Nozzles

Filling and Capping Machine with 8 Nozzles

Lineermac SD8

Features

Brand: LINEERMAC

1 - It has CE certification.

2 - Complies with GMP.

3 – It complies with the food regulations of the Turkish Ministry of Health.

Industries used

1 - Cosmetics Industry: Lotion, Shampoo, acetone, hand cleansing gel, oils…

2 - Pharmaceutical Industry: Syrup, Serum, pesticides,

3 - Food Industry: Turnip juice, Lemon juice, vinegar, cooking oil, soft drinks, fruit juices, liquid sweeteners etc.

4 - Chemical Industry: Liquid detergent, liquid soap, chemical raw materials, lubricating oil, paint, bleach etc.

Machine components

In the filling machine, a capping machine is also connected, it has two functions.

Brand: LINEERMAC

1 - It has CE certification.

2 - Complies with GMP.

3 – It complies with the food regulations of the Turkish Ministry of Health.

Industries used

1 - Cosmetics Industry: Lotion, Shampoo, acetone, hand cleansing gel, oils…

2 - Pharmaceutical Industry: Syrup, Serum, pesticides,

3 - Food Industry: Turnip juice, Lemon juice, vinegar, cooking oil, soft drinks, fruit juices, liquid sweeteners etc.

4 - Chemical Industry: Liquid detergent, liquid soap, chemical raw materials, lubricating oil, paint, bleach etc.

Machine components

In the filling machine, a capping machine is also connected, it has two functions.

Fills and Closes. Label machine, automatic cap feeding machine, product collecting tray,

heat tunnel and Shrink can be added to this system according to the customer's request.

It is a user-friendly and CE-safe machine that is easy to maintain and clean.

One person sorts the empty packaging, another person puts the lids

(automatic lid feeding machine sorts) and another person collects and packs.

Customer's packaging specifications.

Applicable to different shaped bottles and plastic bottles: Our company;

Customer's packaging specifications.

Applicable to different shaped bottles and plastic bottles: Our company;

It specializes in the filling, capping and labeling of PP, PE, PVC, glass bottles,

metal bottles and special material bottles. This machine does not drip,

as it uses a mouth cut, non-drip nozzle system. It has LCD screen and PLC control.

Weight control is done digitally on the screen. It is very simple and easy to use .

Technical Requirements.

The parts in contact with the product to be filled are completely 304 or 316 stainless and the chassis of the product;

Technical Requirements.

The parts in contact with the product to be filled are completely 304 or 316 stainless and the chassis of the product;

It is made of 304 material. It is a machine that complies with the Turkish Ministry of Health and GMP requirements.

It can be produced as a line or piece by piece, as well as "L" and "U" shaped assembly.

The entire filling line is designed according to the needs of the buyer company.

It can be produced as a line or piece by piece, as well as "L" and "U" shaped assembly.

The entire filling line is designed according to the needs of the buyer company.

Technicial Specifications

8 NOZZLES FILLING AND CAP CAPING MACHINE

Filling Volume 1ml (DOUBLE PRINT GIVES 2 LT)

Hour Capacity 2000 lt – 3000 lt

Filling System Volumetric filling system (servo control)

Filling Group 8 filling group AISI 316

Nozzle System No Drip Nozzle with Internal Shutdown

Number of Nozzles 8 Pieces AISI 316

Working Pressure 6-8 Bar

Operating Voltage 220 volts / 50 Hz

Control Voltage 24 V Dc

Control Unit PLC

Lid Screwing Unit Linear Lid Closing System (screw tightening)

Lid Fastening Unit On Linear Lid Closing Unit

Conveyor Unit with Acetal Belt AISI 304 profile

Machine Chassis AISI 304

Conveyor Length 5m+3m Total: 8 Meters (can be made short and long upon request)

Conveyor Width Acetal Belt 80 mm

Cover feeding automatic feeding

Filling Volume 1ml (DOUBLE PRINT GIVES 2 LT)

Hour Capacity 2000 lt – 3000 lt

Filling System Volumetric filling system (servo control)

Filling Group 8 filling group AISI 316

Nozzle System No Drip Nozzle with Internal Shutdown

Number of Nozzles 8 Pieces AISI 316

Working Pressure 6-8 Bar

Operating Voltage 220 volts / 50 Hz

Control Voltage 24 V Dc

Control Unit PLC

Lid Screwing Unit Linear Lid Closing System (screw tightening)

Lid Fastening Unit On Linear Lid Closing Unit

Conveyor Unit with Acetal Belt AISI 304 profile

Machine Chassis AISI 304

Conveyor Length 5m+3m Total: 8 Meters (can be made short and long upon request)

Conveyor Width Acetal Belt 80 mm

Cover feeding automatic feeding

Similar offers

Semi-solid materials filling line

0

TL

New

Manufacturer

Esenyurt, İstanbul

2025/02/14

Carton Filling Machine

0

TL

New

Manufacturer

Esenyurt, İstanbul

2025/02/15

Thermoforming Packaging Machine

1

TL

New

Manufacturer

Esenyurt, İstanbul

2025/02/21

Solid materials filling machine with weighing system (in bags)

0

TL

New

Manufacturer

Esenyurt, İstanbul

2025/03/07

Solid materials packing machine in weight-based system

1

TL

New

Manufacturer

Esenyurt, İstanbul

2025/02/26

Powder filling machine in bags

100

TL

New

Manufacturer

Esenyurt, İstanbul

2025/02/13