Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

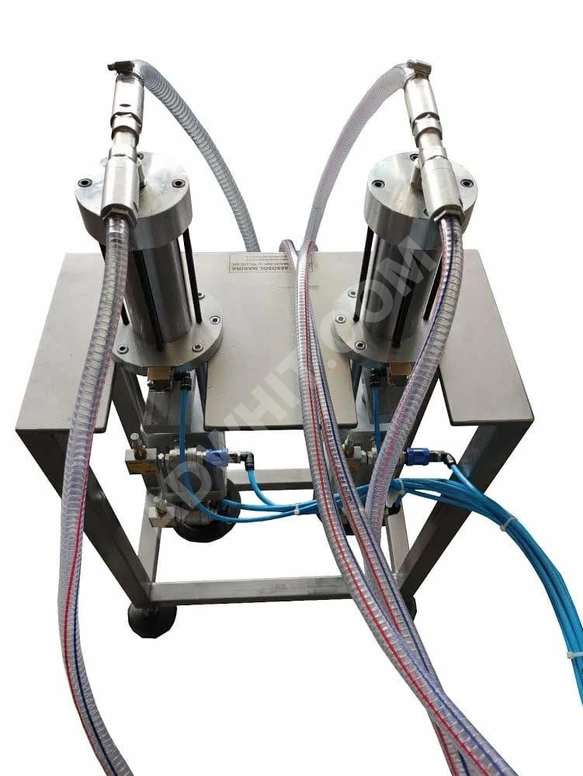

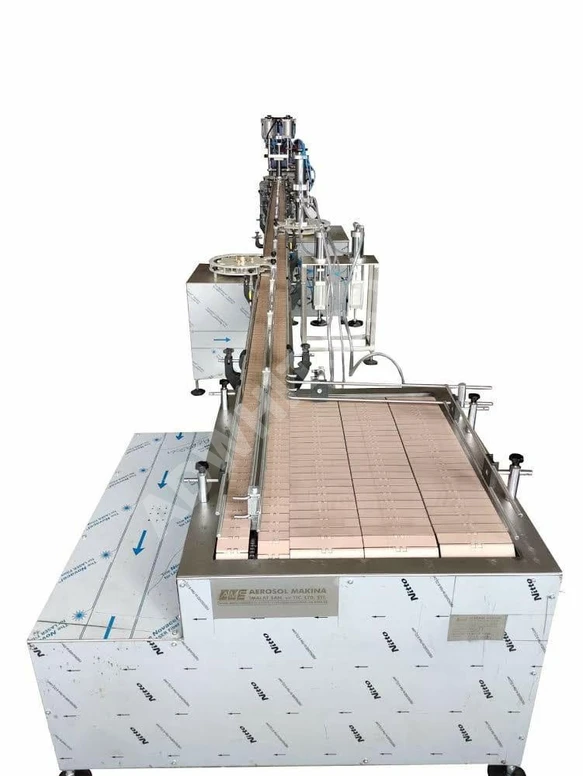

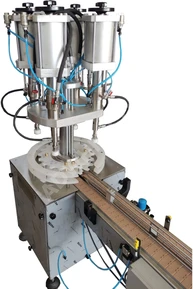

Double-piston aerosol filling machine

Aerosol2

Empty cans are given to the conveyor with the help of feeder. The liquid is filled by two liquid pistons. The valves are then closed by two pistons in the valve closing unit. The products leaving the closing unit enter the four-gas unit. Here the gas is filled. Cans leaving the gas process enter the cap holding unit by a rotary conveyor system. The cap is automatically installed and entered into the ink-jet coding unit.

After the date coding process, the boxes are packed into the collection unit.

The length of the machine is 12 meters. Its weight is 1700 kg. 2 meters wide.

Technical specifications of the product

Gas pressure: 8 bar

Air pressure: 8-10 bar

Production capacity: 60 cans (200 ml capacity)

Maximum gas filling capacity: 400g

Air consumption: 400g

Approximate length: 12 metres

Electrical specifications: 220 volts - 3 kW