Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

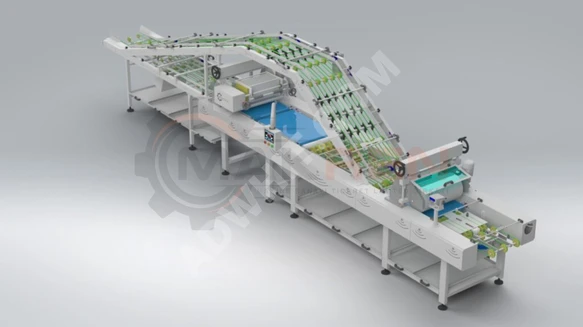

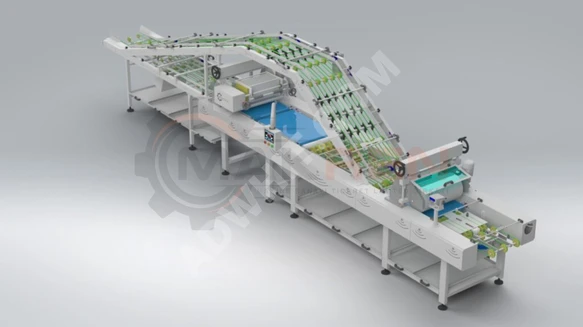

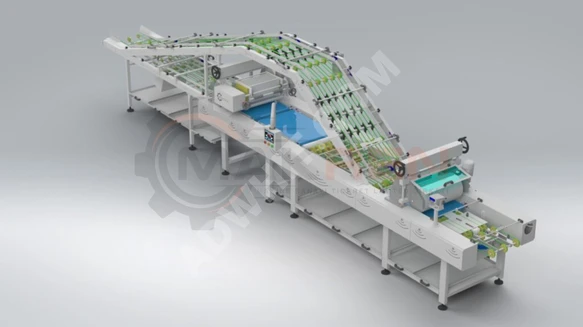

Cream spreading machine for wafers, 40 wafers/minute (12 kW)

A liquid or airy cream is applied to the wafer sheets coming from cooling the sheets and turning them into blocks.

The mass is formed by placing one layer of cream between two sheets, and by placing 5 layers of cream between a maximum of 6 sheets, a total of 11 layers are obtained.

The wafer mass is made with the help of a pneumatic system and the cream can be applied in single or double colours.

The cream is poured onto the wafer coming over the bar with the help of cream scraper blades on a rotating drum. To ensure that the excess cream remaining on the bar is recycled, the stainless steel cream is poured into the rolling cart and transported back to the cream chamber with the help of the pump.

Layered blocks are ironed using an adjustable roller that is installed after the layering system, allowing the cream to spread between the sheets.

There is an optional block weighing unit after the cylinder.

Required grammar rules are easily set and followed on the screen.

Optionally, a nut molding set is additionally used.

Wafer dimensions

The runners and straps can be adjusted to fit wafer sheets ranging from 290 x 470 – 350 x 500.

Cream spreading, one head, 40 wafer sheets/minute, power consumption: 9 kilowatts

Double head spreadable cream, 40 wafer sheets/minute, power consumption 12 kW

Spreading double head with hazelnuts 40 wafer sheets/minute Power consumption 12 kW

Recycling cart power consumption 6 kW

It is made entirely of stainless steel. Automatic cream spreading machines are optionally used to make cream fillings based on a host or film system.

The machine contains an application head, stacking station, printing unit, weighing console and control panel.

Optionally, a second dispensing head can be added to fill cream in different colors or flavours.

It is suitable for applying a minimum of 2 layers and a maximum of 5 layers of cream.

The panels parameters are adjusted automatically.

Turkish payment method: 50% down payment and 50% after loading