Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

Biscuit production line: 18-24 pieces per minute

The line is used to produce flat biscuits automatically.

Biscuit molds are designed in style and thickness according to customer request.

Designed for fuel types: natural gas, LPG or electricity.

Biscuit baking time ranges from 2 to 3.5 minutes depending on thickness and recipe.

An iron stove was used to save energy in the gas system.

The burner provides even distribution on the cooking surface with left and right motion.

The heating system is ignited automatically and can be easily monitored from the control panel.

There is a frequency controlled main motor in the biscuit baking oven.

A frequency controlled impeller pump is used for dough flow.

Pour the dough evenly into the molds at the desired weight.

Adjustable automatic retracting system ensures smooth flow of sheets to the next sheet cooling machine.

The bead cleaning system on the bottom can be controlled automatically or manually from the control panel.

With automatic temperature controller, mold temperature values can be easily monitored from the control panel.

The outer cover of the wafer baking oven is all made of stainless steel.

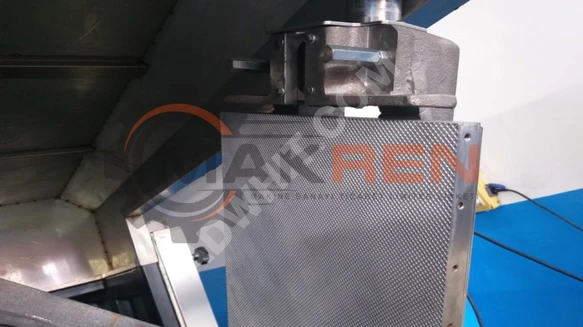

The fork tensioner system is pneumatically controlled.

The gas system is covered with rust-resistant caps to prevent damage.

Kinds of wafer molds and our locking system

Oven 290X470. Block 44 and duration 18-20 minutes

Oven 290X470. Block 60 and duration 24-26 minutes

Oven 350X470. Block 60 and duration 25-28 minutes

Oven 350X470. Block 80 and duration 34-36 minutes

Oven 350X470. Block 90 and duration 40-42 minutes

Oven 350X500. Block 60 and duration 25-28 minutes

Oven 350X500. Block 80 and duration 34-36 minutes

Oven 350X500. Block 90 and duration 40-42 minutes

The line is used to produce flat biscuits automatically.

Baking pans can optionally be designed to create thin or medium depth patterns of cookie sheets.

The baking pans are heated with natural gas, LPG or electricity if desired.

Cooking time can be adjusted between 2 and 3.5 minutes depending on the recipe and desired wafer thickness. Average cooking time is 2.3 minutes.

The system is equipped with energy-saving burners. Each burner can be moved around its own axis to ensure even heat distribution over the entire cooking surface.

The entire heating system is ignited automatically and monitored on the screen.

oven; Frequency controlled main motor, frequency controlled impeller pump used for dough flow, automatic paper removing system, automatic heat control device, stainless steel coating, closed exhaust cover on dough flow station, automatic controlled tong tensioning system It has pneumatic, bottom bead cleaning system and control panel and is equipped with control cabin.

Turkish payment method: 50% down payment and 50% after loading.