Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

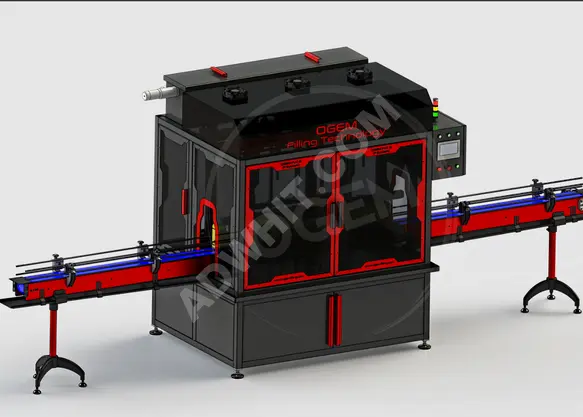

Automatic packaging machine with a capacity of 1500-1700 units/hour

Technical Specifications

✓ Fully automatic packing machine.

✓ Operated by vacuum system. Contains 4/6/8/10/12 custom discharge nozzles.

✓ Weight limits of the machine: upon request.. (Weight range: from 100 ml to 1000 ml)

✓ The filling machine operates in a temperature range from 5 degrees to 80 degrees.

✓ Machine accuracy: At constant air pressure (8 atto-750 l/min), constant temperature and homogeneous products, overall weighing accuracy is + – 1%.

✓ The funnel of the machine is made of PVC.

✓ The funnel has an automatic level control system. When the funnel is full, the product inlet valve automatically closes or a signal is sent to the pump feeding the machine with product to stop or start it.

✓ Filling nozzles: It contains a vacuum filling system, and is available with 4/6/8/10/12 filling nozzles upon request.

✓ Nozzles can be easily adjusted to suit different bottle sizes. It has a tip locking mechanism to prevent dripping and bottle contamination.

✓ Adjusting the weight of the machine: It is easy to adjust the weight from the PLC screen of the machine.

✓ It contains an additional adjustment mechanism to adjust the differences between the filling nozzles.

✓ Materials used in manufacturing the machine: The machine body is covered with rust-resistant electrostatic paint.

✓ Machine covers are made of PVC. The machine nozzles are made of PVC and 904L high acid resistant material. The nozzle tips are made of titanium.

✓ Filling capacity of the machine: At constant air pressure (8 atto-750 l/min) the capacity is approximately 1500 - 1700 units/hour for a 500 ml package depending on the type of package.

✓ (Capacity is an estimate and cannot be guaranteed.)

✓ The packing machine uses a conveyor belt with a total length of 6 meters. The body is made of PVC, and the conveyor belt is made of polypropylene. The speed of the conveyor belt can be controlled from the control panel.

✓ To operate the machine, you need air with a pressure of 8 ATO (compressor) and electricity with a voltage of 380 volts.

Note: The capacity of the filling machine may vary depending on the chemical properties of the product to be filled (e.g. foam).

Areas of use

Chemistry and cosmetics:

Liquid detergents, colognes, sterilizers, lotions, medical liquids, chlorine, etc