Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

Automatic machine for filling perfume bottles

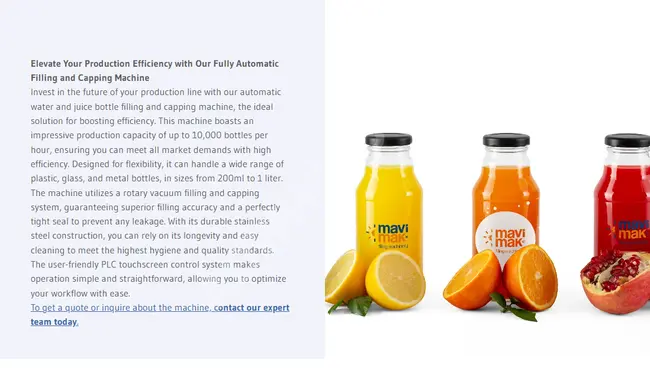

Automatic Perfume Bottle Filling Machine 15-150ml 2000 Bottles/Hour:

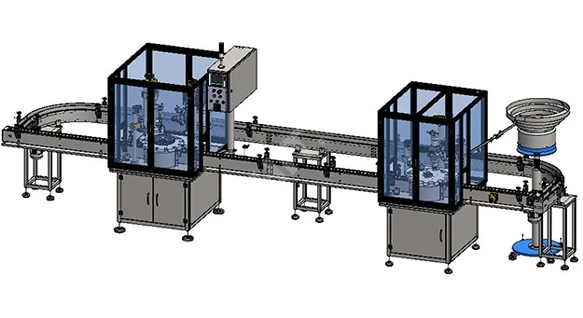

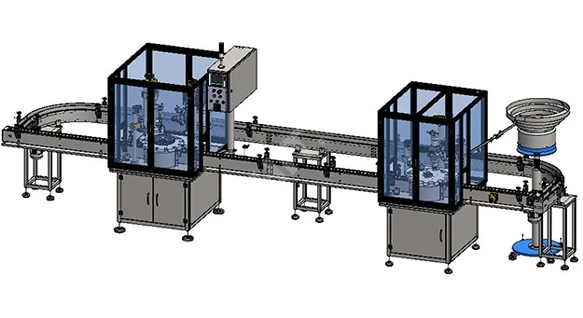

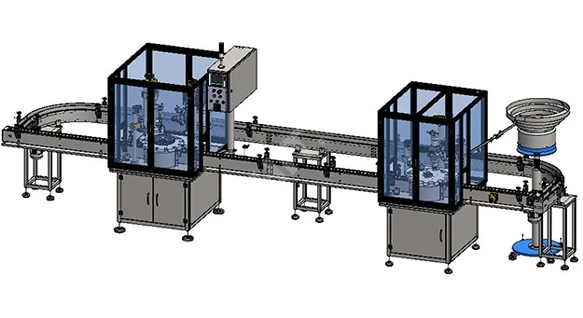

Automatic perfume filling machine fills liquids such as perfume and cologne in glass and hard plastic, and fills with a vacuum system without the need to adjust the weight. Therefore, no leakage occurs in the filled bottle. This machine cannot be used for filling soft bottles. In the automatic perfume bottle filling machine, the perfume bottles move on a rotating conveyor and fill with a vacuum system using the perfume filling head. On the same conveyor, perfume bottles are double sealed. Perfume filling and valve closing machine is an automatic equipment used in the cosmetics industry. This machine fills the perfumes into the bottles and then ensures that the valve is closed properly. The process is usually automated or semi-automatic.

This machine usually has the following basic functions:

- Filling: Filling the correct amount of perfume into the specified bottles. This process is done using vacuum systems.

- Close valves: Close the valve installed on the nozzle of the perfume bottle properly. This process is crucial to ensure no leakage.

- Labeling (optional): A labeling system can be integrated into the machine to apply labels to the product after the filling process is complete if necessary.

- Speed and capacity: Perfume filling and valve closing machines can work at different speeds and various capacities. This can be adjusted according to production needs.

- Hygiene and sterilization: It is necessary that cosmetic products comply with hygiene standards. Therefore, all surfaces that come into contact with perfume must be easy to clean and sterilize.

- Flexibility: It should be adjustable to different bottle types and sizes. This allows them to be used in the packaging of various products.

- Control systems: It contains a control panel to monitor, adjust and manage the machine’s operation process. This enables the operator to use the machine effectively.

- Safety features: It has appropriate safety measures and emergency stop systems to ensure the safety of operators.

- Efficiency and performance: It is important that the machine performs filling and valve closing operations quickly and efficiently.

These types of machines are used to speed up production processes and increase automation in the cosmetics industry. It also plays an important role in improving product quality and compliance with hygiene standards.

Technical Specifications:

- Process type: automatic filling and covering

- Filling capacity: 15 ml - 150 ml

- Filling speed: 2000 bottles/hour

- Filling accuracy: ±0.1 ml

- Control system: electromechanical

- Power consumption: 1.5 kW

- Electrical power: 380 volts 50 Hz

- Air pressure and consumption: 6 bar - 1000 ml/min

- Materials: The materials used to make the machine. Corrosion-resistant 304 and 316 stainless steel is preferred.

- Machine dimensions: width 850 mm, length 6000 mm, height 1000 mm

- Weight: 500 kg

- Safety features: The machine has a protective cabin and safety switches to ensure the safety of the operator