Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

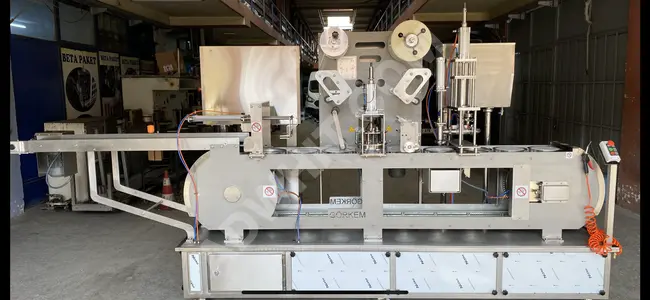

Automatic liquid filling machine with 4 nozzles

This filling machine features an automatic design and is very easy to use. This machine is powered by a servo motor and volumetric system, allowing it to perform precise filling operations of liquid products quickly and reliably. The touch screen interface allows you to easily adjust fill settings. 7-inch PLC screen, with English and Turkish language options, provides comfortable user experience.

This filling machine is designed in different sizes and shapes to suit your products, and works compatible with mechanical and electronic systems. After the filling process is completed, the machine body and parts can be easily cleaned, ensuring compliance with hygiene standards.

The packing process begins when employees manually feed packages of products onto a conveyor. Product packages advanced on the conveyor are detected by the packing machine's sensors and stopped at the packing area. The machine pulls the product from the tank and begins the filling process through 4 filling nozzles. After setting the filling weight from the screen, the machine automatically completes and cuts the filling process.

The number of nozzles on the filling machine is directly proportional to the number of products to be produced in a given period of time. You can evaluate different nozzle options according to your needs or inform us of your requirements.

After the filling process is completed, the filled products advance on the conveyor and the empty product packs stop again under the filling nozzles to repeat the filling process. Thanks to the automatic level control system, the product inlet valve closes when the tank is full, and a signal is sent to the pump feeding the machine to stop or restart the process. In this way, the filling machine can work for hours without interruption, eliminating the need to monitor the product level inside the tank.

If you want to improve your packaging line, you can add a cap sealing machine behind the filling machine to seal the caps of packaged products, and then add an automatic labeling machine to apply your labels. In this way, you can convert your filling line into a fully automatic line and increase production efficiency