Property for Sale

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

US Dollar

42.8261

Euro

50.2416

Saudi Riyal

11.4309

Pound Sterling

57.3329

Kuwaiti Dinar

139.4657

United Arab Emirates Dirham

11.6609

Egyptian Pound

0.9009

Iraqi Dinar

0.0327

Bahraini Dinar

113.5750

Qatari Riyal

11.7667

Libyan Dinar

7.9008

Omani Rial

111.3842

Jordanian Dinar

59.2011

Algerian Dinar

0.3301

Moroccan Dirham

4.6720

Syrian Pound

0.0039

AEF 3500 Automatic Aerosol Filling Machine

İstanbul / Esenyurt

Status

New

Advertiser

Manufacturer

Brand

Enes Makina

Details

Address

İstanbul / Esenyurt / Akçaburgaz mah.

Offer number

00379173

Offer date

2024/06/05

Communication Languages

AEF 3500 Automatic Aerosol Filling Machine

Some operations are performed manually in the standard line:

Manual work: valve insertion, upper tapping, covering, and inkjet printing.

The automatic aerosol filling machine first receives the boxes coming from the conveyor into the liquid filling section.

After manually inserting the valves, the cans move to the gas filling section without tightening the valve.

The surfaces of the boxes coming out of the gas filling section are manually fixed, then the lids are manually closed, and after the optional inkjet unit, the products are ready for packaging.

Automatic aerosol filling machine

Production capacity: 50-60 pieces

Manual work: valve insertion, upper tapping, covering, and inkjet printing.

The automatic aerosol filling machine first receives the boxes coming from the conveyor into the liquid filling section.

After manually inserting the valves, the cans move to the gas filling section without tightening the valve.

The surfaces of the boxes coming out of the gas filling section are manually fixed, then the lids are manually closed, and after the optional inkjet unit, the products are ready for packaging.

Automatic aerosol filling machine

Production capacity: 50-60 pieces

Similar offers

Ayran and yogurt filling machine

0

TL

New

Owner

Başakşehir, İstanbul

2025/11/12

Filling, packaging, and cooling line for metal containers

0

TL

New

Manufacturer

Başakşehir, İstanbul

2025/09/23

Filling, capping, and labeling line for plastic and glass bottles

0

TL

New

Manufacturer

Başakşehir, İstanbul

2025/09/23

High-speed rotary machine for filling high-viscosity liquids

0

TL

New

Manufacturer

Başakşehir, İstanbul

2025/09/23

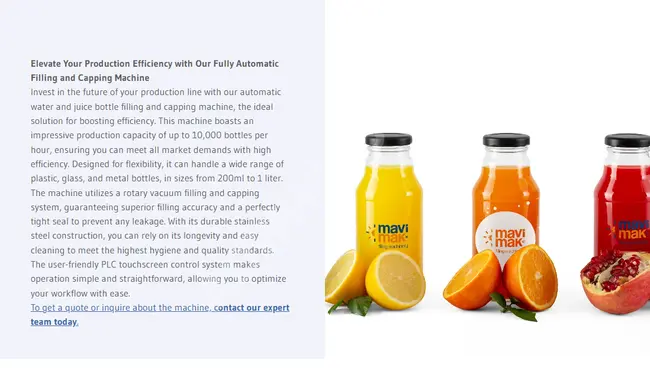

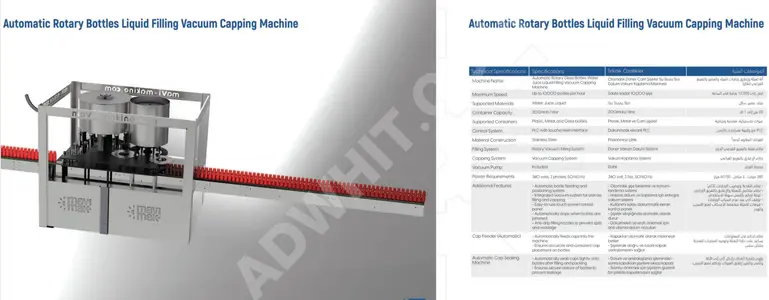

Automatic machine for filling liquids and vacuum capping

0

TL

New

Manufacturer

Başakşehir, İstanbul

2025/09/23

Rotary Filing and Capping Machine

0

TL

New

Manufacturer

Başakşehir, İstanbul

2025/09/13