Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

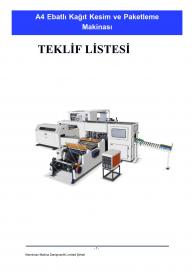

A4 paper production line and cutting and packaging machine

Equipment Technology

As the technology for our machine, we explain the functions and workflow related to paper products: unwinding → cutting → conveying → collecting → packaging.

1. It adopts a PLC touch screen and servo motor for fixed-length cutting control.

2. It uses photoelectric, pneumatic, electrical, and air sensors to control the conveying system, providing ease of use, high accuracy, good stability, and low-noise operation.

3. This machine includes a frequency converter timer, automatic counting, shutdown with alarm, magnetic powder tension control, it can cut vertically, and uses a blower to remove waste.

4. This machine can be equipped with a 1-roll, 2-roll, or 4-roll loading system.

5. With packaging machine.

The copy paper production line contains two units of machines. It can cut the copy paper roll into A4-size sheets and bundle the sheets into sets. The automatic production line is a medium-speed machine with three different options. You can choose a single roll, double roll, or four roll feeding slitting unit with different production capacities. The automatic bundling machine is separate in the production line and can be connected to different slitting units.

Maximum unwinding roll width: 1100 mm

Maximum unwinding roll diameter: 1400 mm

Speed

200 times/minute

Accuracy

±0.2 mm

Total power

20 kW

Weight

8000 kg

Dimensions

19300x7900x2000 mm