Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

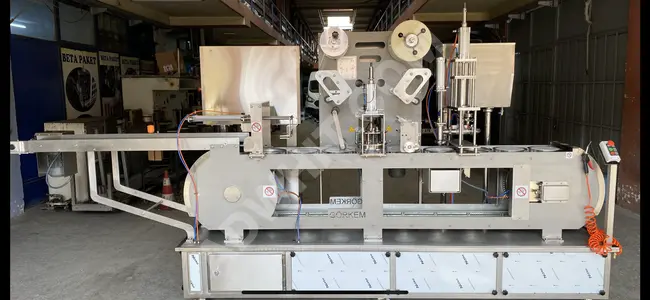

A machine for labeling the front and back surfaces with a capacity of 5000 pieces per hour

Fako FK-DS Front and Back Surface Marking Machine provides high accuracy and efficiency in the heavily used front and back surface marking operations. For areas where production volumes are relatively low, semi-automatic systems would be the ideal solution. The product is placed in a simple holder and manually transferred to the conveyor. When the tag is applied, the product is automatically installed by the system and the tag placement is completed with high precision.

There is no restriction on product size in this system. The product mounting equipment can be easily changed in a few simple steps, reducing time loss when processing different types of packages. It is recommended to install a fully automatic system to meet maximum accuracy requirements in medium and high quantity production.

The system moves synchronously with the conveyor belt to ensure perfect labeling. Fako labeling systems offer suitable solutions for your packaging and application in the field of front and back surface labeling.

Main Features:

- High efficiency: greatly increases production speed with labeling capacity up to 5000 units per hour.

- Accurate marking: Provides high accuracy with marking stop sensitivity of ±0.5mm.

- Versatile application: Easily adapts to different types and sizes of packages, and the product mounting equipment can be changed with simple steps.

Technical Specifications:

- Capacity: 5000 units/hour (depends on product size and label)

- Marking speed: 50 m/min

- Marker stop sensitivity: ±0.5mm

- Marker width: 15-140mm (including liner)

- Roll label reel: max outer diameter 300mm

- Storage formats: 100 formats to store product and tag

- Reel holder: mechanical winding system and screw lock

-Main body: anodized aluminum reel discs

- Quick release: “push/pull” mechanical drive unit

- Motor: Stepper motor (Sanyo Denki)

- Rewinder: Foldable liner locking system

- Tag sensor: adjustable support (not suitable for transparent tags)

- Blade distribution: adjustment angle up to 90°

-Control unit: integrated with touch screen operation panel

- Adjusting the distribution speed: controlled by a potentiometer

- Adjust offset and delay

- Marks counter and overcoming missing marks

- Paper tearing alarms

- Distribution speed control: optional encoder

- Interfaces for external alarms and signals

- Power source: single phase, 240 V, 50/60 Hz

- Adjust the reverse speed

-Angle adjustment system: for conical or angled products

Customer Advantages:

- Efficiency and speed: Increases production efficiency with high marking capacity.

- Accurate marking: Accurate and consistent marking application makes your products perfect.

- Flexibility: Suitable for different sizes and types of products, and can be used in various industries.

- Durability and Reliability: Made of high-quality materials such as anodized aluminum, making it long-lasting and reliable.

Application areas:

- Food and Beverage: Ideal for labeling the front and back surfaces of products.

-Cosmetics: Provides accurate labeling of cosmetic packaging.

- Pharmaceuticals: Offers suitable labeling solutions for pharmaceutical bottles and packages.

-Other industries: Meets the needs of front and back surface labeling in various industries.

Why choose Fako?

- Economical Solutions: Provides high quality labeling solutions at an affordable cost.

- Advanced Technology: Uses the latest technology to ensure high accuracy and reliability.

- Comprehensive Support: Our dedicated team is ready to help you choose and implement the labeling solution that best suits your business needs.

for further information...

Improve your labeling process with the Fako FK-DS 5000 units/hour front and back surface labeling machine.

For more information or to order, contact us today. Our professional team is here to provide the most suitable solutions for your business needs