Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

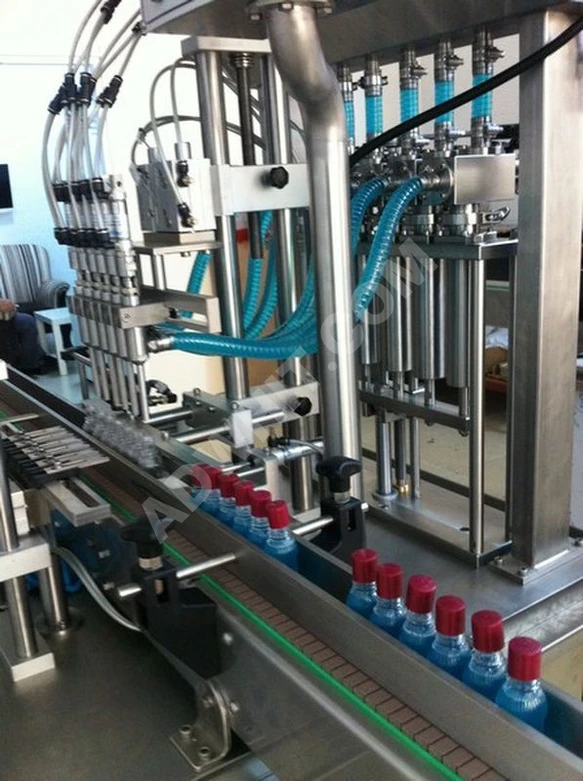

A machine for filling and capping small bottles with a capacity of 10-100 ml

Small hotel shampoo filling and capping machine is a machine that performs automatic filling and capping of liquids and small bottles used in hotels and similar establishments. These machines are used to provide hygiene and personal care products to hotel guests. In addition, these machines are also suitable for filling and sealing operations of similar products such as hair conditioner, body lotion, or shower gel. The basic functions of small hotel shampoo cap filling and sealing machine are:

Automatic filling: The machine automatically fills the shampoo into bottles based on a predetermined volume, reducing human errors and speeding up the filling process.

Speed and Efficiency: The small hotel shampoo filling machine operates much faster than manual filling operations, reducing labor costs and increasing production efficiency.

Dosage Control: The machine can be set to fill an equal amount of shampoo into each bottle, maintaining product quality and providing a consistent customer experience.

Cleanliness standards: Cleanliness standards in hotels are very important. Small hotel shampoo filling machine operates in hygienic conditions to maintain product quality.

Bottle recognition and arrangement: The machines can recognize bottles of different sizes and place them in the correct position, which speeds up the filling process and ensures accuracy.

Adjusting the filling speed: The viscosity of different products varies, so the filling speed in these machines can be adjusted to suit different types of products.

Capping and labeling (optional): Some machines can close caps and label bottles after filling.

Small hotel shampoo cap filling and sealing machine plays an important role in the hotel industry in terms of product delivery and service quality. These machines speed up processes and maintain product quality, helping hotels provide better service to their customers.

Technical Specifications:

Packing set: 304 quality stainless steel

Sealing elements: PTFE TEFLON and VITON

Control systems: Touch screen and electro-pneumatic system (LG PLC and LG 7-inch touch screen + Pemaks pneumatic system) Language options: Turkish and English

Anti-foaming system: Bottom and top filling nozzle system for foamed products (6 heads) manufactured to order.

Filling system: Pemaks pneumatic system

Packing size: 10 - 1000 ml

Filling capacity: 3600 units/hour

Control voltage: 24V DC

Operating voltage: 380V 50Hz 10A

Energy consumption: 1 kW/h

Dimensions: H 2200mm x 900 x 900 x 3000mm

Conveyor: (3 meters acetal sheet)

Protection chambers: Plexiglass coating on 304 quality body (for filling and sealing)

Cap closing machine (screw cap closing):

Body: 304 quality stainless steel

Carrier plate: (3 meters acetal sheet)

Conveyor motor: 380V 0.37kW (S40/21)

Energy consumption: 1 kW/h

Closing caps: Closing screw caps

Dimensions: H 1800mm x 900 x 900 x 3000mm