Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

A double-sided bottle labeling machine

4000 - 6000 BTU/H Double Sided Bottle Labeling Machine: KILIÇ Packing Machines

New factory double sided bottle labeling machine

Our company manufactures complete turnkey production and packaging lines.

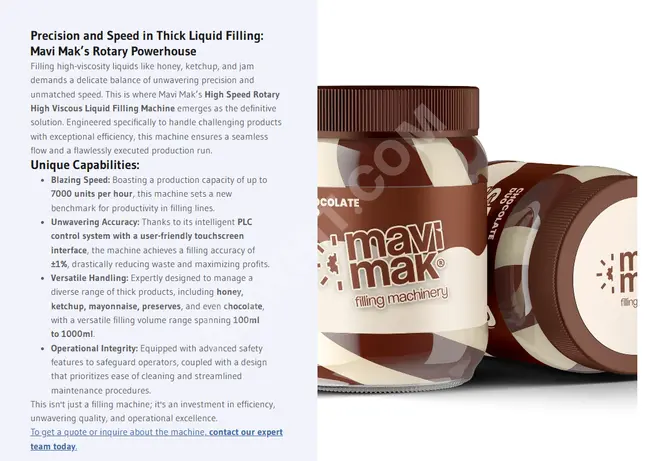

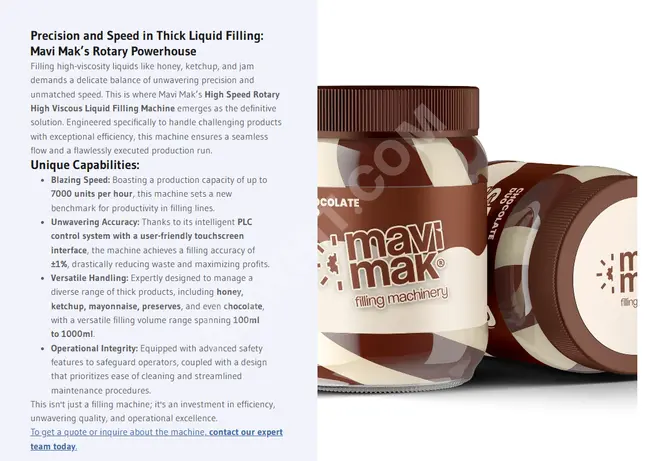

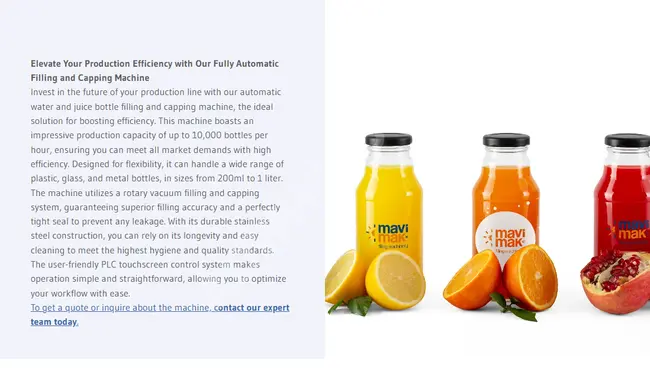

Example: Jam line production plant, ketchup line production plant, mayonnaise line production plant, honey packing plant, establishing a complete beauty factory.

In our company all kinds of automatic machines of special design are manufactured.

Our company has the local product certificate.

Our company is supported by the KOSGEP ARGE Industrial Application and Innovation Support Programme.

Our machines are exported to all over the world with 24-hour maintenance services provided.

Products we pack:

Food sector:

Honey, molasses, tahini, jam, marmalade, olive paste, pomegranate molasses, syrup, rapeseed syrup, ketchup, fruit juice, mayonnaise, vegetable oils and all granular products.

Beauty sector:

Liquid soaps, detergents, shampoo, antifreeze, acetone, cologne, sanitizers, antibacterial gel, perfume, all buclet products, etc.

Pharmaceutical sector:

All combinations of liquid products, syrup, solution, eye drops, cream, essential water, mouthwash (gargle), etc.

Industrial sector:

All kinds of liquid and semi-liquid agricultural pesticides, agricultural fertilizers, mineral oil, motor oil, cutting oil, fallow oil, etc.

Technical Specifications:

The Automatic Double Sided Labeling Machine attaches self-adhesive labels to various package surfaces such as metal cans, glass, bottles, PET, PVC Kueks without problems. In addition, an optional coding device is available that prints the serial number and production date on labels.

Label width: 10-150mm

Label length: 10-300mm

Label reel diameter: 250mm

Label exit length: 5-30m/min

Number of labels: 4000 – 6000 units/hour

Control screen: Panasonic P.L.C touch screen

Model motor: 5 KNW STEP 2

Operating voltage: 220V 50Hz 3A

Control voltage: 24 VDC

Stop label: Precision electronic switch

Options for working with transparent and opaque labels

Product sensor: reflective optical sensor

Body: High quality 304 stainless steel

Carrier: Sigma Aluminum 2.5m 90-135-180g

Conveyor motor: 380V - 0.37 kW

Conveyor speed control: with frequency converter

Winding and strip combination: 380 V - 0.37 kW (S 40 / 21)

Power consumption: 0.5 kW/h

Company warranty: two years

Spare parts supply: 10 years