Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

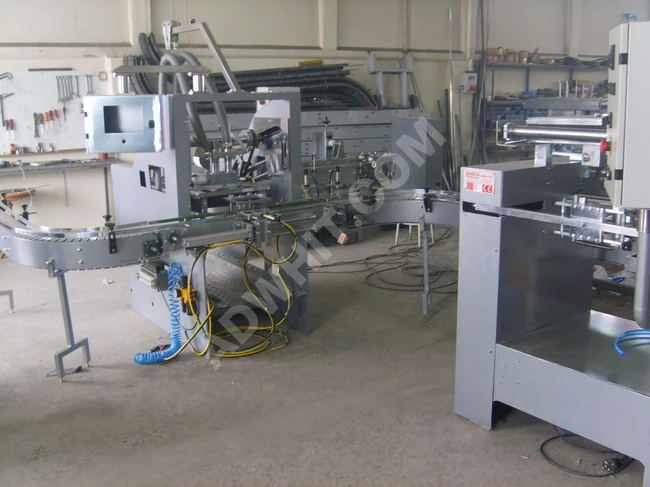

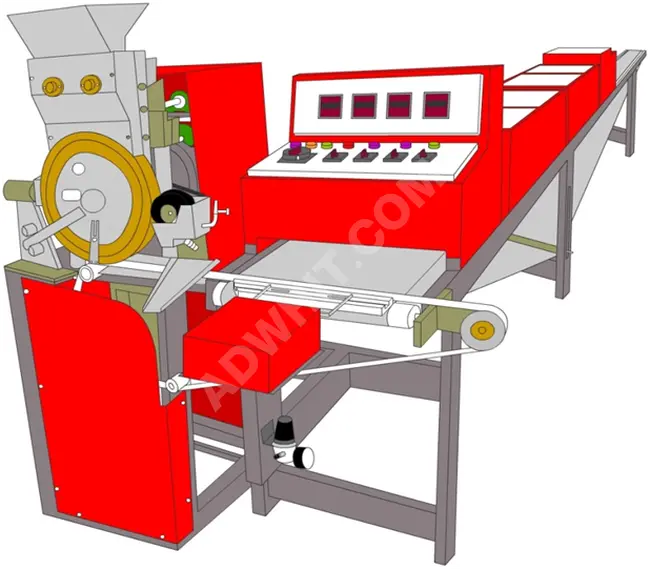

A bottle labeling machine with a micrometric system

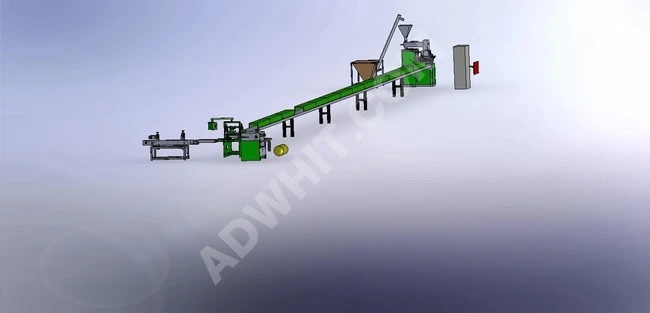

Our labeling machine is designed to apply OPP labels around cylindrical bottles by cutting them from the reel and sticking them completely.

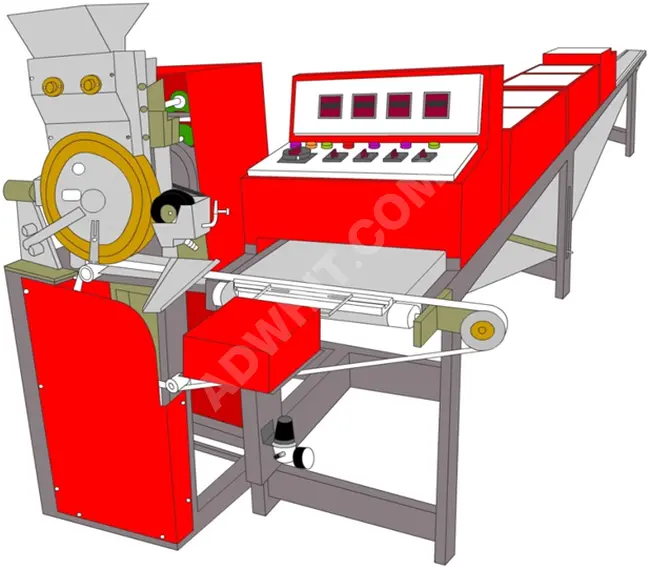

Controlled by PLC, it is fully automatic and controlled via touch screen.

Our machine has line-type working characteristics, and sticks labels using hot glue.

The labels can be applied to glass, PET, PVC and tin cans.

The set of labels can be changed quickly, making moving from one bottle to another very easy.

The machine has a bottle filling and organizing system at the entrance.

The electric control panel is connected to the machine body, making it easy to transport and install. The glue system is attached to the machine body to facilitate transportation.

Technical Specifications:

The speed of the machine varies depending on the length of the label and the characteristics of the bottle.

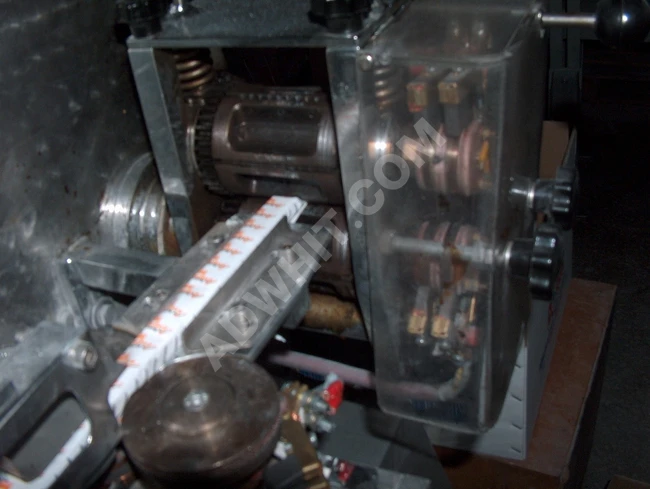

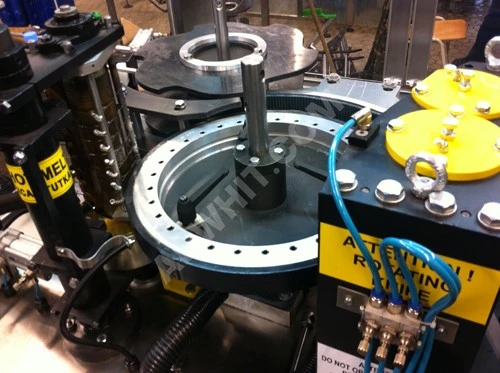

The label is pulled from the reel, passes through special automatically compressed rollers, and then adheres to the vacuum system on the vacuum roller in reverse.

A very small amount of glue is applied to both ends of the label by an advanced glue application system, so that the last end of the label overlaps the first end and wraps around the bottles.

The label tension system has a tension system that ensures synchronization with the machine's working speed.

The machine has an internal and external lighting system.

There is a special conveyor system at the outlet, which facilitates easy connection of conveyors.

The label cutting system can be adjusted with micrometer precision