Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

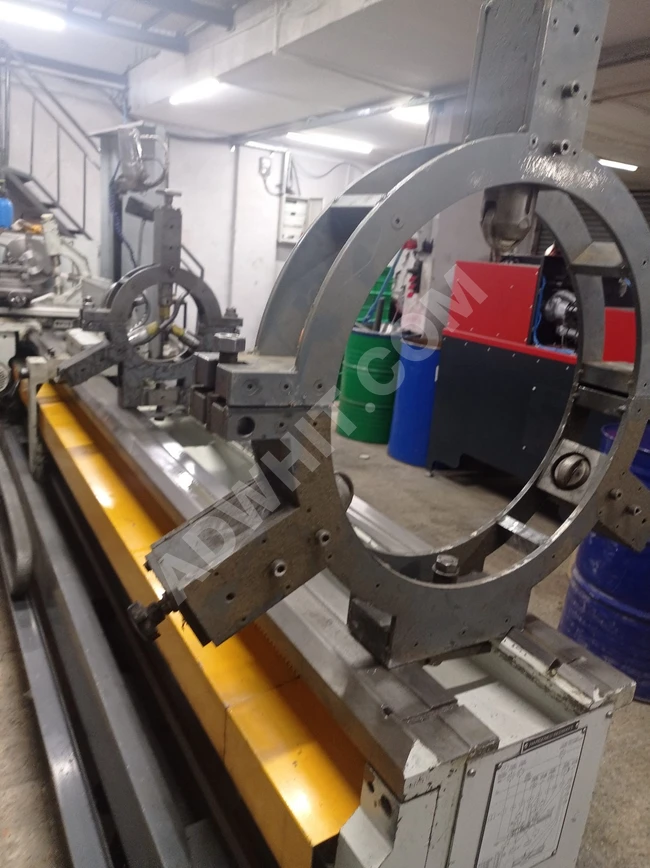

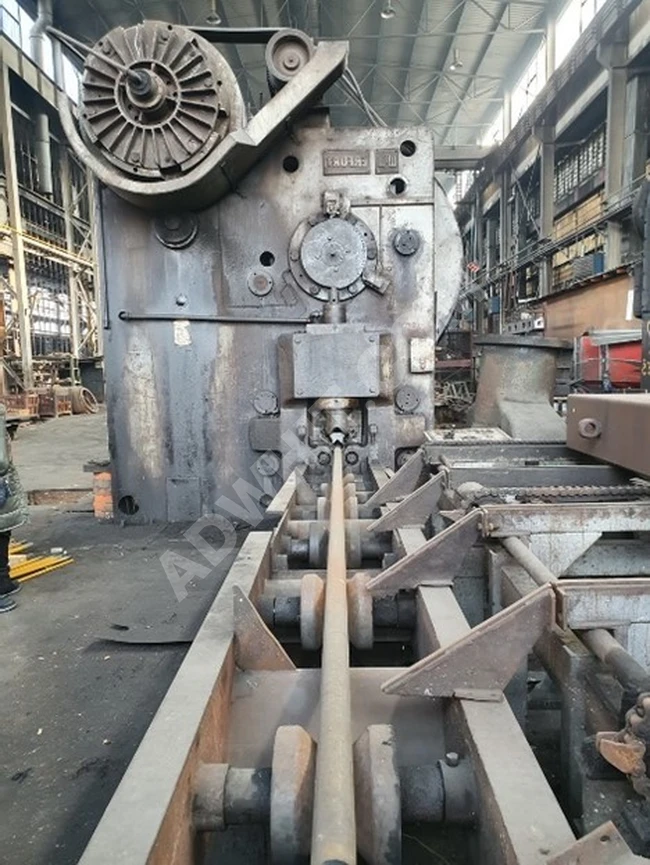

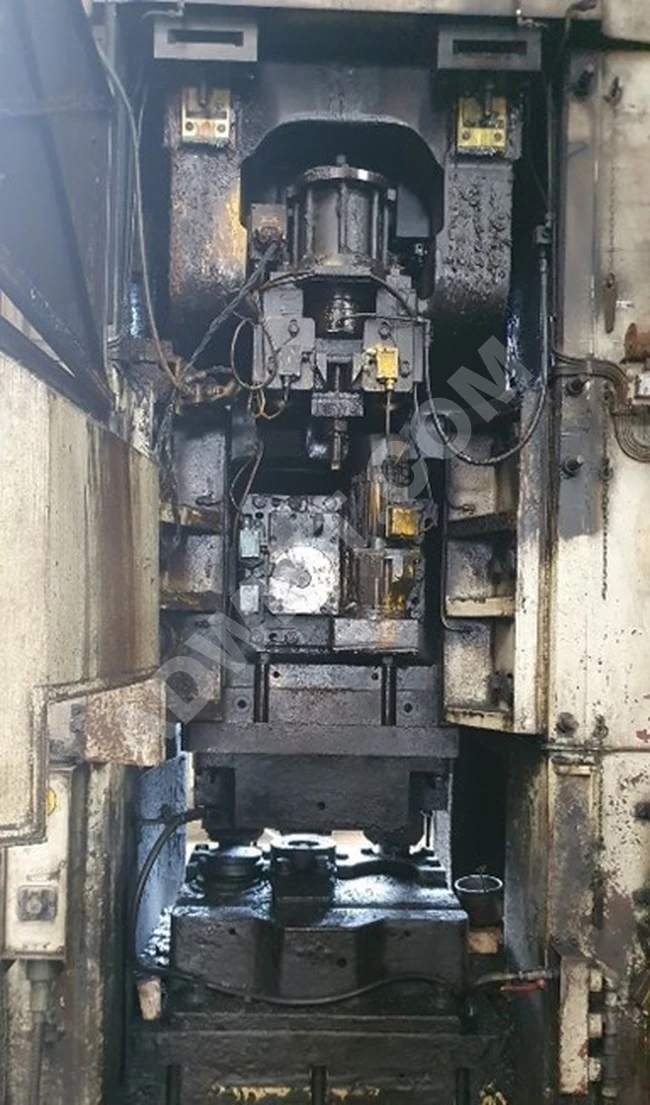

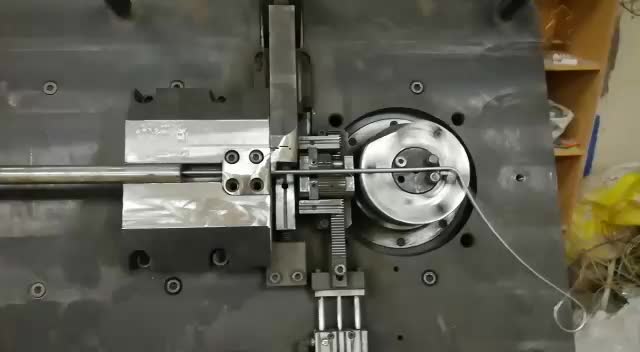

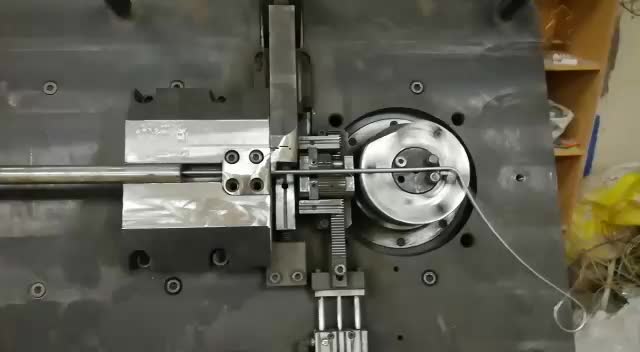

2D CNC WIRE BENDING MACHINE

2D CNC Wire Bending Machine

Cnc 2D Wire Bending Machine

It is computer (CNC) controlled and works with special net machine software compatible with the current Windows Operating System.

The product to be produced is defined through the Elo brand 21” Touch Monitor and Wi-Fi keyboard unit.

All parts planned to be produced will be examined in detail and Roll Reels and cross-section distance pieces suitable for the previously requested and/or specified wire diameters will be prepared.

Remote Technical Service Module is available optionally. While Operator Support is provided with the Remote Technical Service Module, Technical Error and/or Technical Failure situations are detected and rapid action is taken.

Optionally, defined Barcode Printer integration can be provided into the system. Thus, product-based label output can be obtained automatically at the end of each production in line with the specified quantity/piece.

With the LOOP function, definitions of repeated beats are simplified.

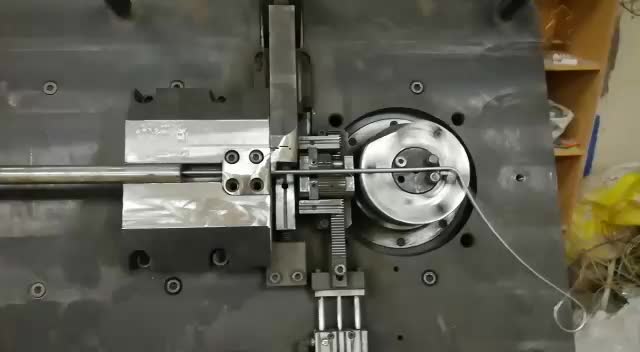

It is driven by two Gearmotor Servo Torque Motors. The turret area can rotate 180 degrees and thus, 2 different radiuses can be obtained in the bending areas.

Special software is used. All software updates made within the scope of electronic warranty are updated free of charge and made available to the customer.

Straightening system ø3mm. ~ ø10mm. It is in the form of 2 (two) pieces and a single group, horizontal and vertical, which can straighten the measuring wire.

ø3mm ø10mm working from coil. size ST37, C 1006, C 1008, C1010 quality wire with 3 (Three) axes movement, max. 90 ~ 95 m./min. It is a machine that can form/shape 2 (Two) dimensional (2D) wire at feeding speed.

There is a 1Ton Capacity coil loading unit that works integratedly.

Kollmorgen brand Servo Motor and Driver Groups are preferred.