Property for Rent

Cars for Sale

Used Furniture

Motorcycles

Machines and Tools

Professions and Services

Job Listings

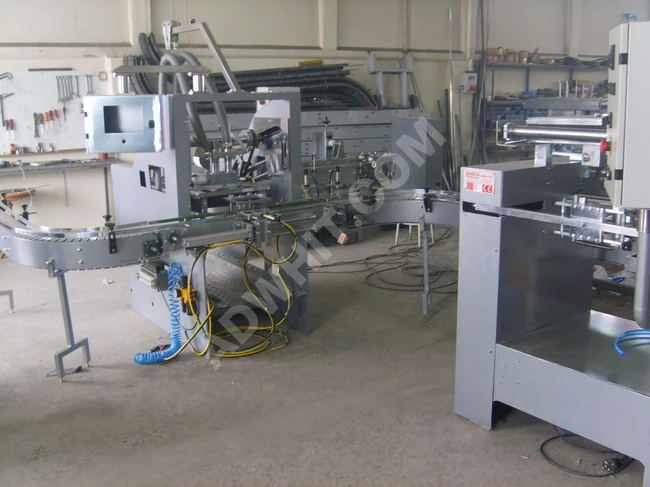

Thermoforming, Filling, and Packaging Machine (Butter, Margarine...)

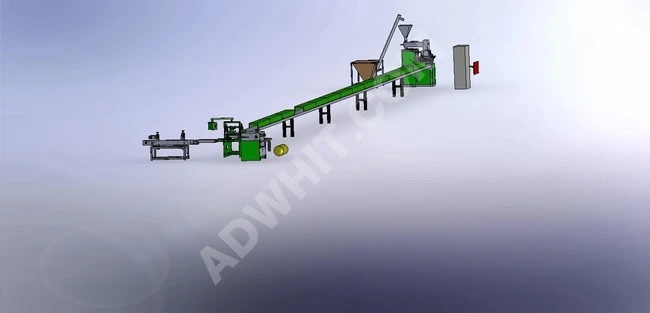

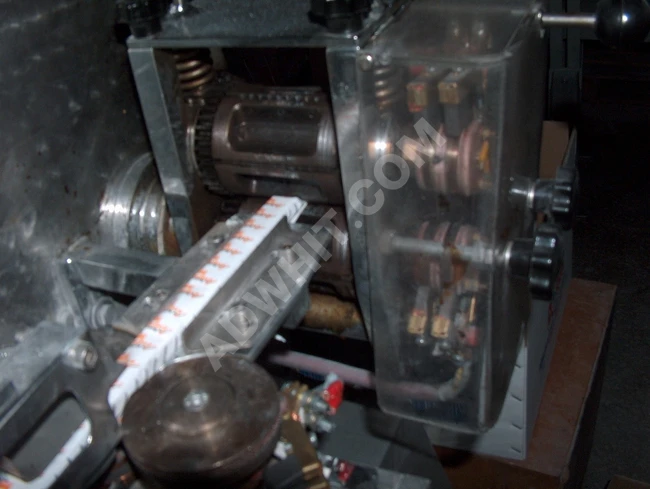

YZ thermoforming machines are mainly used for automatic filling and sealing applications, often used for water, juice, ketchup, mayonnaise, honey, jam, chocolate spread, nut butter, cream cheese, coffee, milk, yogurt... The machine is used for filling and sealing. It is a cam driven machine; This means that the forward movement of the plastic film is carried out by a mechanical cam system that provides a very high performance of up to 35 revolutions per minute.

Butter and margarine are milk derivatives, and their filling and sealing using thermoforming is critical to ensuring that potential food safety risks in the packaging process are evaluated and eliminated.

In addition, butter and margarine are high-viscosity liquids, so filling differs from standard viscous liquids because they must be volumetric filling. All surfaces of the filling unit must be well polished to leave almost no roughness in the flow paths of butter and margarine to maintain food safety.

Cehuma's YZ series is very suitable for filling and sealing butter and margarine at high speeds while observing all safety measures, in different weights and sizes depending on the customer's needs.

We also offer our customers a complete turnkey solution that includes end-to-end robots to carton, package, and shrink each product ready for shipping.

Technical Specifications

Power (strokes/minute) | 15-35

Cursor (step) (mm) | 70-200

Bottom film width (mm) | 150-500

Bottom film thickness (m) | 550-1200

Bottom film material | PVC/PET/PS/PP

Upper film material | AL+PET

Machine length (mm) | 5,500-11,000

Power consumption (kW) | 8-25

Electricity supply | 3x380V. 50 Hz.

Compressed air required (bar) | 6-8

Cooling water (°C) | 10-16

Advantages

Stainless steel body

Servo technology

Safety standards compatible with EC regulations

Wide packaging design options

Programmable advance speed

Wide touch screen

Multiple language options

Precise doses

Advanced cutting/punching technology