عقارات للبيع

عقارات للإيجار

سيارات للبيع

أثاث مستعمل

دراجات

آلات ومعدات

المهن والخدمات

فرص عمل

عقارات للإيجار

سيارات للبيع

أثاث مستعمل

دراجات

آلات ومعدات

المهن والخدمات

فرص عمل

الدولار الامريكي

34.5467

اليورو

36.0147

الريال السعودي

9.2129

الجنيه الاسترليني

43.3470

الدينار الكويتي

112.4034

الدرهم الاماراتي

9.4076

الجنيه المصري

0.6955

الدينار العراقي

0.0264

الدينار البحريني

91.6626

الريال القطري

9.4965

الدينار الليبي

7.0720

الريال العماني

89.7340

الدينار الاردني

48.7191

الدينار الجزائري

0.2574

الدرهم المغربي

3.4416

الليرة السورية

0.0027

خلاط جبن

207.28 TL

Sakarya / Serdivan

الجهة المعلنة

المالك

سنة الصنع

2021

تفاصيل اضافية

العنوان

Sakarya / Serdivan / Beşköprü mah.

رقم العرض

00259838

تاريخ العرض

2021/12/20

لغات التواصل

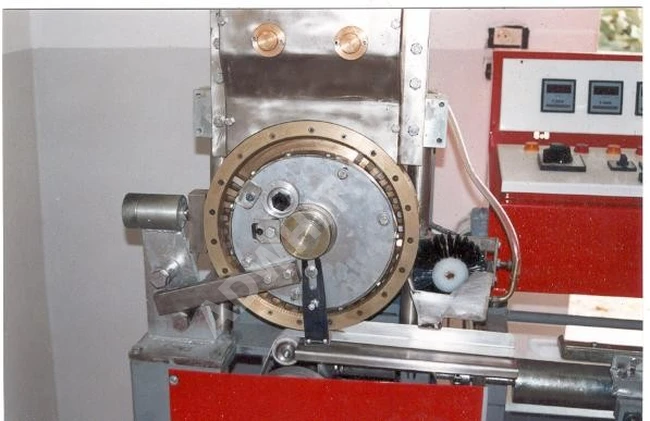

خلاط جبن

MOZZARELLA CHEESE COOKING MACHINE

TECHNICAL SPECIFICATIONS

- Full capacity of body is 600 kg

- Batch capacity is 450 kg.

- AISI304 quality stainless steel material

- All plastic and derivative material are convenient to food and cleaning detergents

- PLC and touch panel

- Batch type processing

- Automatic opening/ closing of product inlet/ outlet

- 2 motors conjoint gearboxes

- Independent two augers- counter rotating

- Augers; maximum of 160 rpm speed with PLC-controlled speed control devices; directions of movement, rotation speed and time can be adjusted according to the recipe

- Augers with frequency inverter

- Homogenous and effective mixing

- Safety sensors against accidents

- Automatic temperature control

- Electromagnetic flowmeter

- 10 different recipes can be saved in memory

- Steam treatment (filter & separator & trap)

- Direct steam heating through 8 nozzles

- Indirect steam heating from the wall which is double jacketed

- Intermittent steam can be supplied by PLC system

- Extruder for storage & stretching

- Weighting system (load cell)

- Conveyor/ Lifter for raw materials

- Safety cage for lifter (machine stops automatically if safety cage is opened)

عروض مشابهة

طباخ جبن الكريم ( ستيفان )

0

TL

جديد

المصنع

Arifiye, Sakarya

2024/10/17

مكينه تحميص قهوة

85,200

TL

مستعمل

المالك

Gaziosmanpaşa, İstanbul

2024/08/30

مطحنة بن

44,300

TL

مستعمل

المالك

Gaziosmanpaşa, İstanbul

2024/08/30

ماكينة تكعيب السكر النصف اتوماتيكية TYO – 40 CP

30,000

TL

جديد

المصنع

Yenimahalle, Ankara

2024/09/09

مكنة تقطيع الفستق واللوز بشكل صنوبري

4,000

TL

جديد

المصنع

Şehitkamil, Gaziantep

2024/09/30

مكتة تقشير اللوز )فلاسة)

3,500

TL

جديد

المصنع

Şehitkamil, Gaziantep

2024/09/28